6C13G11

5-48

1

2

3

4

5

6

7

8

9

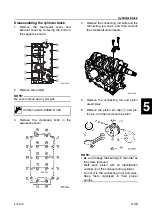

NOTE:

• Align the alignment marks

g

on the con-

necting rod cap and connecting rod.

• Apply engine oil to the connecting rod bolts

before installation.

9.

Install half of the bearings into the crank-

case.

NOTE:

• Install the main bearings in their original

positions.

• Insert the projection of each bearing into

the slots in the crankcase.

10. Apply sealant to the mating surface of

the crankcase.

NOTE:

Do not get any sealant on the main bearings.

11. Install the crankcase onto the cylinder

block.

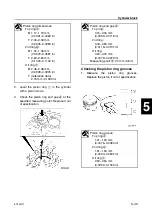

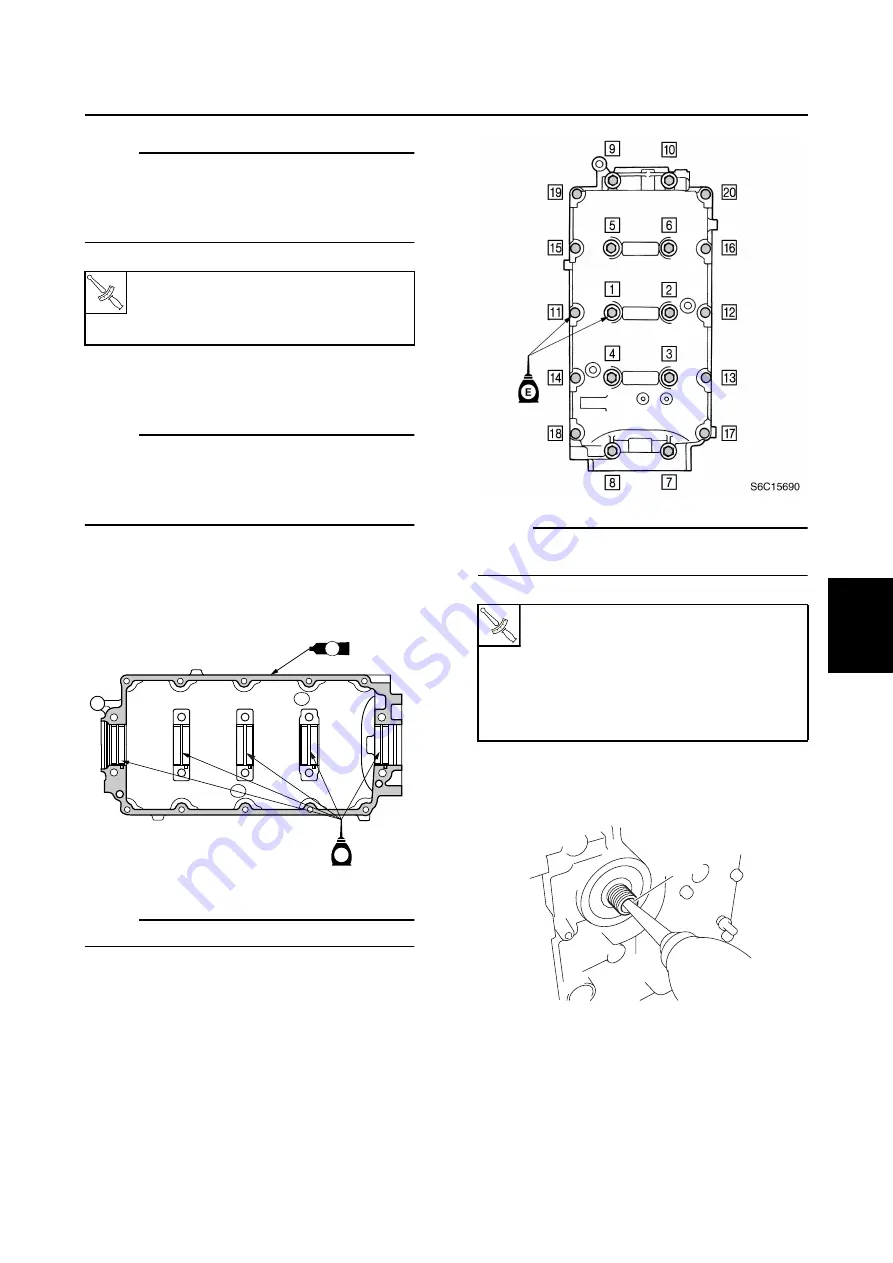

12. Tighten the crankcase bolts to the speci-

fied torques in two stages and in the

sequence shown.

NOTE:

Apply engine oil to the crankcase bolts before

installation.

13. Before installing the oil filter, be sure to

supply engine oil to the oil passage

h

.

T

R

.

.

Connecting rod cap bolt:

1st: 6 N·m (0.6 kgf·m, 4.4 ft·lb)

2nd: 17 N·m (1.7 kgf·m, 12.5 ft·lb)

S6C15760

GM

E

T

R

.

.

1

–

0

Crankcase bolt (M8):

1st: 15 N·m (1.5 kgf·m, 11.1 ft·lb)

2nd: 30 N·m (3.0 kgf·m, 22.1 ft·lb)

A

–

J

Crankcase bolt (M6):

1st: 6 N·m (0.6 kgf·m, 4.4 ft·lb)

2nd: 12 N·m (1.2 kgf·m, 8.9 ft·lb)

S6C15770

h

Summary of Contents for F50F

Page 1: ...F50F FT50G F60C FT60D SERVICE MANUAL 6C1 28197 3G 11 290551 ...

Page 4: ......

Page 48: ...SPEC Specifications 2 25 6C13G11 MEMO ...

Page 190: ...LOWR Lower unit 6 47 6C13G11 Shimming FT50 FT60 6 ...

Page 195: ...6C13G11 6 52 1 2 3 4 5 6 7 8 9 MEMO Backlash FT50 FT60 ...

Page 221: ...6C13G11 7 24 1 2 3 4 5 6 7 8 9 Steering arm ...

Page 249: ...6C13G11 7 52 1 2 3 4 5 6 7 8 9 MEMO Power trim and tilt electrical system ...

Page 272: ...ELEC Electrical systems 8 21 6C13G11 MEMO ...

Page 301: ...6C13G11 i 5 1 2 3 4 5 6 7 8 9 Index MEMO ...

Page 303: ......

Page 304: ...YAMAHA MOTOR CO LTD Printed in the Netherlands Jul 2004 1 2 1 CR E_2 ...