6C13G11

6-10

1

2

3

4

5

6

7

8

9

Checking the propeller shaft housing

1.

Clean the propeller shaft housing using a

soft brush and cleaning solvent, and then

check it for cracks. Replace if necessary.

2.

Check the teeth and dogs of the reverse

gear for cracks or wear. Replace the

gear if necessary.

3.

Check the bearings for pitting or rum-

bling. Replace if necessary.

Checking the propeller shaft

1.

Check the propeller shaft for bends or

wear. Replace if necessary.

2.

Measure the propeller shaft runout.

3.

Check the dog clutch, shift slider, and

shift plunger for cracks or wear. Replace

if necessary.

Assembling the propeller shaft

assembly

1.

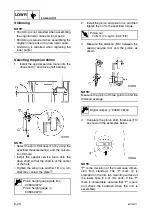

Install the dog clutch as shown.

NOTE:

Install the dog clutch

1

with the “F” mark

a

facing toward the shift plunger.

Assembling the propeller shaft

housing

1.

Install the needle bearing into the propel-

ler shaft housing to the specified depth.

NOTE:

Install the needle bearing with the manufac-

ture identification mark

a

facing toward the

oil seal (propeller side).

Needle bearing attachment

8

:

90890-06614

Driver rod L3

9

: 90890-06652

Runout limit: 0.02 mm (0.0008 in)

S6D56510

Driver rod L3

1

: 90890-06652

Needle bearing attachment

2

:

90890-06614

Depth

b

:

3.25

±

0.25 mm (0.128

±

0.010 in)

Summary of Contents for F50F

Page 1: ...F50F FT50G F60C FT60D SERVICE MANUAL 6C1 28197 3G 11 290551 ...

Page 4: ......

Page 48: ...SPEC Specifications 2 25 6C13G11 MEMO ...

Page 190: ...LOWR Lower unit 6 47 6C13G11 Shimming FT50 FT60 6 ...

Page 195: ...6C13G11 6 52 1 2 3 4 5 6 7 8 9 MEMO Backlash FT50 FT60 ...

Page 221: ...6C13G11 7 24 1 2 3 4 5 6 7 8 9 Steering arm ...

Page 249: ...6C13G11 7 52 1 2 3 4 5 6 7 8 9 MEMO Power trim and tilt electrical system ...

Page 272: ...ELEC Electrical systems 8 21 6C13G11 MEMO ...

Page 301: ...6C13G11 i 5 1 2 3 4 5 6 7 8 9 Index MEMO ...

Page 303: ......

Page 304: ...YAMAHA MOTOR CO LTD Printed in the Netherlands Jul 2004 1 2 1 CR E_2 ...