6C13G11

7-48

1

2

3

4

5

6

7

8

9

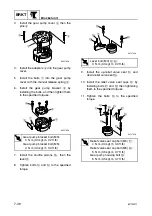

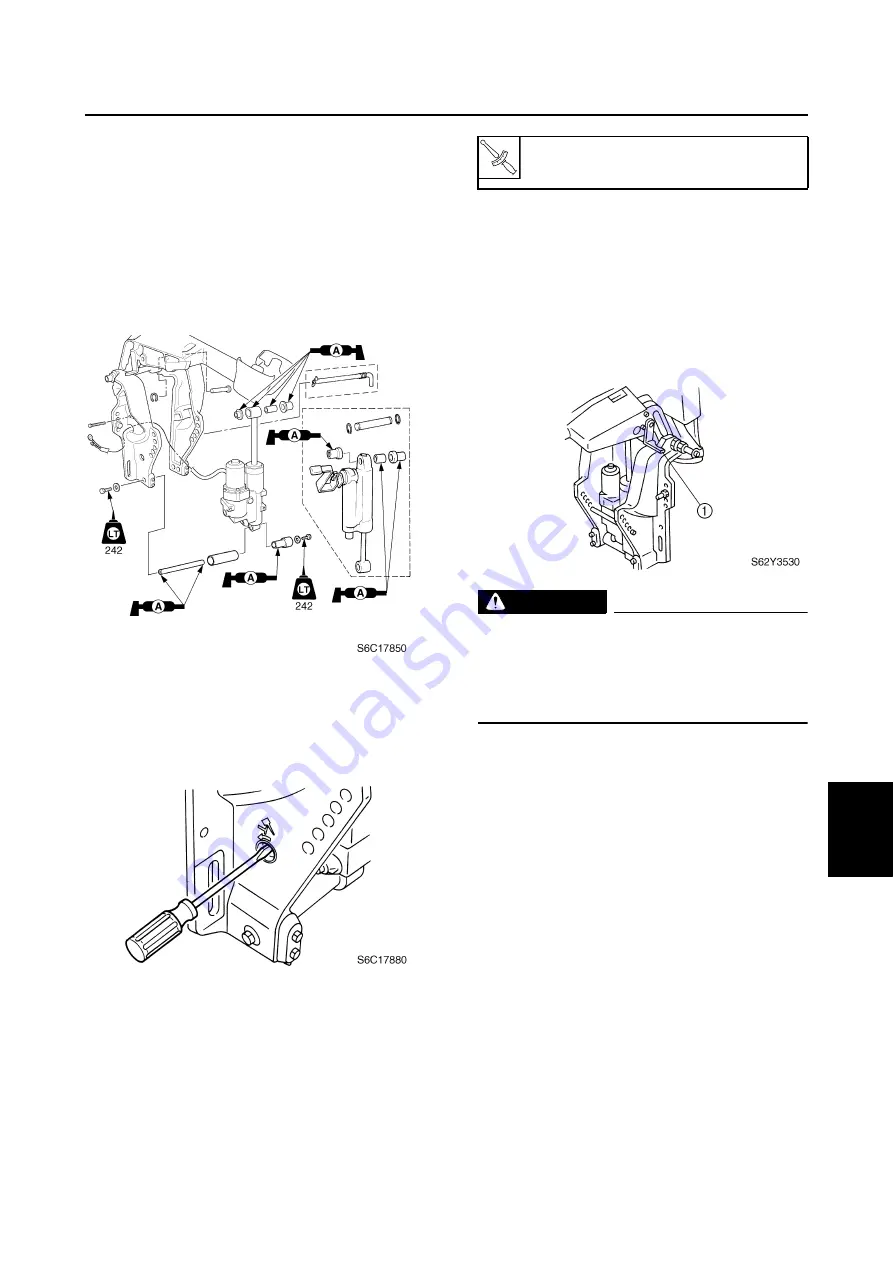

6.

Route the PTT motor leads through the

hole, and then install the plastic tie.

7.

Connect the ground lead to the bottom of

the power trim and tilt unit, and then

tighten the bolt.

8.

Install the tilt pin (hydro tilt model).

Bleeding the power trim and tilt unit

(built-in)

1.

Fully turn the manual valve counterclock-

wise.

2.

Fully tilt the outboard motor up, and then

release it to let it lower by its own weight

four to five times.

3.

Tighten the manual valve by turning it

clockwise.

4.

Let the fluid settle for 5 minutes.

5.

Push and hold the power trim and tilt

switch in the up position to check that the

outboard motor is fully tilted up.

6.

Support the outboard motor with the tilt

stop lever

1

.

WARNING

After tilting up the outboard motor, be

sure to support it with the tilt stop lever.

Otherwise, the outboard motor could sud-

denly lower if the power trim and tilt unit

should lose fluid pressure.

T

R

.

.

Manual valve:

2 N·m (0.2 kgf·m, 1.5 ft·lb)

Summary of Contents for F50F

Page 1: ...F50F FT50G F60C FT60D SERVICE MANUAL 6C1 28197 3G 11 290551 ...

Page 4: ......

Page 48: ...SPEC Specifications 2 25 6C13G11 MEMO ...

Page 190: ...LOWR Lower unit 6 47 6C13G11 Shimming FT50 FT60 6 ...

Page 195: ...6C13G11 6 52 1 2 3 4 5 6 7 8 9 MEMO Backlash FT50 FT60 ...

Page 221: ...6C13G11 7 24 1 2 3 4 5 6 7 8 9 Steering arm ...

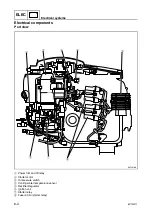

Page 249: ...6C13G11 7 52 1 2 3 4 5 6 7 8 9 MEMO Power trim and tilt electrical system ...

Page 272: ...ELEC Electrical systems 8 21 6C13G11 MEMO ...

Page 301: ...6C13G11 i 5 1 2 3 4 5 6 7 8 9 Index MEMO ...

Page 303: ......

Page 304: ...YAMAHA MOTOR CO LTD Printed in the Netherlands Jul 2004 1 2 1 CR E_2 ...