3-20

TM-401 User’s Guide

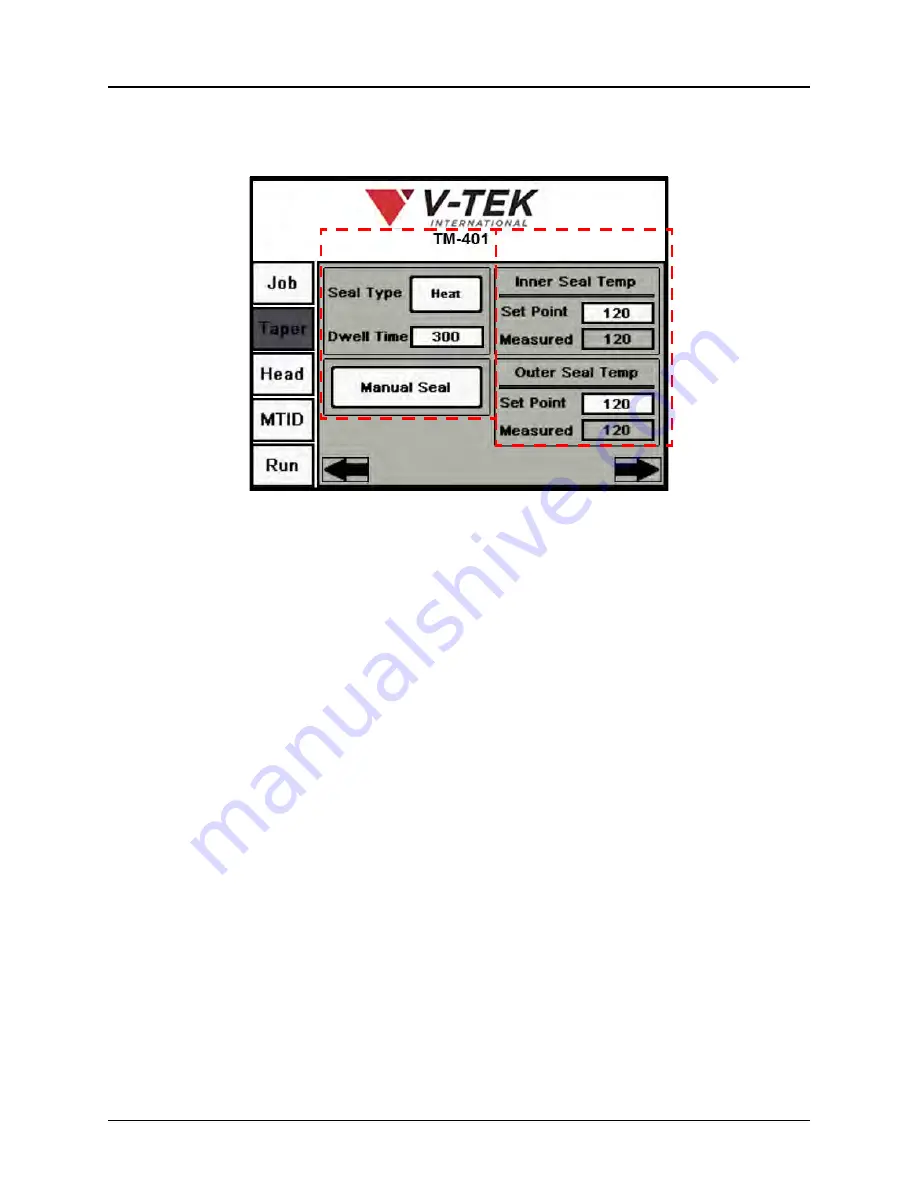

Taper Tab

D292104.6.fm

The third

Taper Setup

screen focuses on

Sealer Settings

. It will vary in appearance depending on

the type of sealer selected. In the example below, the selected

Seal Type

is

Heat

.

A.

The

Seal Type

button toggles between

Heat

seal and

PSA

seal.

The

Dwell Time

field is only active when heat seal is

ON

. Dwell time refers to the

amount of time that the

Heat Seal Shoes

are in contact with the

Cover Tape

.

Enter the desired dwell time in milliseconds in this field.

The

Manual Seal

button activates the sealer to perform one seal.

B.

The

Set Point

field allows the user to select the

Heat Sealer

set point, or target

temperature. Press the field to open the keypad, then enter the desired tempera-

ture in degrees Celsius.

The

Measured

field shows the current

Heat Sealer

temperature in degrees Cel-

sius.

Note:

The TM-401 accommodates a wide range of carrier tapes and cover tapes. Set-

tings may vary from one tape product to another. The recommended starting point is 90°

C. The maximum recommended operating temperature is 160° C

.

The temperature for

each seal shoe should be increased or decreased as needed after running a peel force

test.

Taper Screen 3

A

B

Summary of Contents for TM-401

Page 4: ......

Page 74: ...3 32 TM 401 User s Guide Run Tab D292104 6 fm ...

Page 146: ...5 44 TM 403 User s Guide Configure Inspection D292104 16 fm ...

Page 158: ...6 12 TM 401 User s Guide Preparing to Run a Pre programmed Job D292104 8a fm ...

Page 188: ...7 30 TM 401 User s Guide Adjusting PSA Seal Quality D292104 9a fm ...

Page 204: ...Appendix A Sensors A 6 SMC ZSE30 Vacuum Sensor D292104 11 fm ...

Page 208: ......

Page 284: ......

Page 286: ...Service and Parts Contacts 61053915 fm Page 2 ...

Page 288: ...TM 401 Document List D292104 15b fm Page 2 ...

Page 290: ......

Page 291: ......