Reelmaster 7000

DPA Cutting Units

Page 8 -- 38

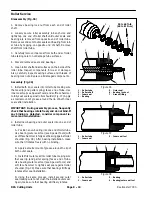

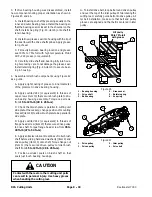

3. If drive bearing housing was disassembled, install

new components noting proper orientation as shown in

Figures 45 and 46.

A. Install bearing on shaft by pressing equally on the

inner and outer bearing races. Install the bearing so

that the bearing seal is closest to the shoulder on the

shaft. Install snap ring (Fig. 45, item 6) onto shaft to

retain bearing.

B. Install new grease seal into housing with the lip of

the seal toward the drive shaft splines. Apply grease

to lip of seal.

C. Fill cavity between bearing location and grease

seal 50% to 75% full with high temperature Mobil

XHP--222 grease (or equivalent).

D. Carefully slide shaft and bearing fully into hous-

ing bore taking care to not damage the grease seal.

Install retaining ring (Fig. 45, item 5) to secure bear-

ing in housing.

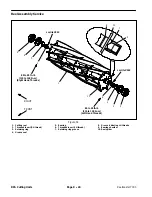

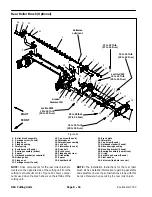

4. Assemble roller brush components using Figure 42

as a guide.

A. Apply a light coating of grease to inner diameter

of the grommet in drive bearing housing.

B. Apply Loctite #242 (or equivalent) to threads of

cap screws (item 13) that secure brush plate to driv-

en bearing housing assembly. Torque cap screws

from

15 to 19 ft--lb (20 to 25 N--m)

.

C. Check that brush plate is parallel to cutting unit

side plate. If necessary, change position of mounting

bracket (item 29) to allow brush plate to be parallel to

side plate.

D. Apply Loctite #242 (or equivalent) to threads of

flange head screw (item 20) that secures drive pulley

to drive shaft. Torque flange head screw from

35 to

40 ft--lb (47 to 54 N--m)

.

E. Apply antiseize lubricant to splines of roller brush

shaft before sliding hardened washer(s) (item 9) and

driven pulley (item 10) onto shaft. Torque flange nut

(item 11) that secures driven pulley to roller brush

shaft from

15 to 19 ft--lb (20 to 25 N--m)

.

F. Position excluder seals on brush shaft so that

seals just touch bearing housings.

CAUTION

Contact with the reel or other cutting unit parts

can result in personal injury. Use heavy gloves

when handling the cutting reel.

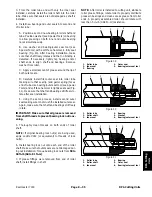

G. To install drive belt, loop belt around driven pulley

and over the top of the idler pulley. While rotating the

cutting reel, carefully guide belt onto drive pulley. Af-

ter belt installation, make sure that belt and pulley

grooves are aligned and that belt is centered in idler

pulley.

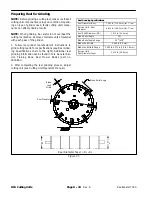

1. Bearing housing

2. Drive shaft

3. Ball bearing

4. Grease seal

5. Retaining ring

6. Snap ring

Figure 46

Fill cavity

50 to 75% full

with grease

2

6

3

4

1

5

1. Drive pulley

2. Driven pulley

3. Idler pulley

4. Drive belt

Figure 47

2

3

1

4

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

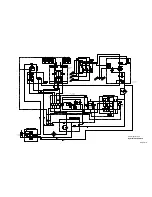

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

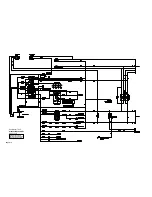

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...