Reelmaster 7000

DPA Cutting Units

Page 8 -- 13

Leveling Rear Roller

The precision machined components of the cutting unit

frame keep the rear roller and cutting reel in alignment

(parallel). If the side plates are disassembled or as the

cutting reel wears, a limited amount of side plate adjust-

ment is possible to make sure that the cutting unit is

properly aligned.

1. Place the assembled cutting unit on a surface plate.

2. Make sure that bedknife is properly adjusted to cut-

ting reel.

3. Using the surface plate, check if rear roller is level to

cutting reel by using a 0.005” (0.13 mm) shim at each

end of rear roller. If the shim will pass under the roller at

one end but not the other, a frame adjustment should be

made.

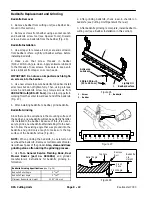

4. Loosen, but do not remove, the three (3) shoulder

bolts that secure the side plate to the frame opposite the

side that is not level (Fig. 12).

5. Adjust the position of the side plate to parallel the

rear roller and cutting reel. Then, tighten the shoulder

bolts to a torque from

27 to 33 ft--lb (37 to 44 N--m)

.

6. After tightening the side plate, recheck the rear roller.

If necessary, loosen and adjust second side plate.

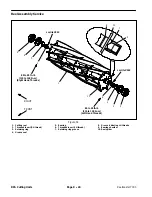

7. If rear roller is still not level after adjusting both side

plates, check to see if cutting reel is tapered (see Pre-

paring Reel for Grinding in the Service and Repairs sec-

tion of this chapter). If cutting reel is not tapered and rear

roller is not level, a 0.010” shim (part number 107--4001)

is available to allow additional rear roller adjustment.

Use the shim on one side of the rear roller and install it

between the rear roller bracket and roller shim (Fig. 13).

8. After leveling rear roller, complete cutting unit set--up

and adjustment sequence.

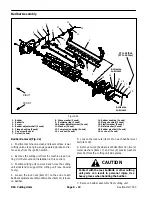

1. Bedbar

2. Bedbar adjuster screw

3. Spring tension lock nut

4. Shoulder bolt

Figure 12

2

4

1

3

4

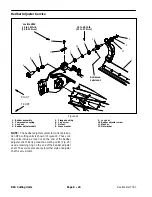

1. Rear roller assembly

2. Rear roller bracket

3. Carriage screw

4. Flange nut

5. Roller shim

6. 0.010” shim (if needed)

Figure 13

1

2

3

4

5

6

DP

A

C

utting

Units

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...