Reelmaster 7000

Page 3 -- 15

Kubota Diesel Engine

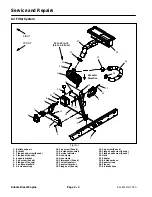

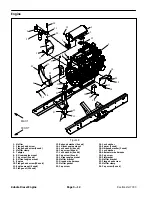

8. Install fan motor and fan assembly (Fig. 11).

A. Carefully position fan motor, fan and motor brack-

et assembly to radiator.

B. Secure fan motor bracket to radiator with six (6)

cap screws and flange nuts.

C. Remove caps and plugs placed in hoses and fit-

tings during removal to prevent contamination.

D. Connect hydraulic hoses to cooling fan motor

(see Hydraulic Hose and Tube Installation in the

General Information section of Chapter 4 -- Hydraulic

System).

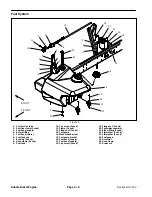

9. Position upper radiator shroud to the radiator. Secu-

re shroud to the radiator and lower radiator bracket with

removed fasteners (see Radiator Installation in this sec-

tion). Make sure that clearance between shroud and fan

is at least 0.180” (4.6 mm) at all points.

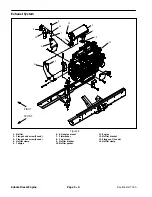

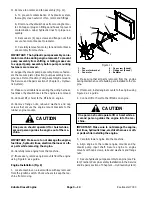

10.Connect throttle cable to engine (Fig. 9):

A. Secure throttle cable swivel to speed control le-

ver with lock nut.

B. Place throttle cable under cable clamp.

C. Adjust throttle cable position in cable clamp so

that engine governor lever contacts the high speed

stop bolt at the same time that the throttle lever con-

tacts the end of the slot in the control console.

D. Tighten cable clamp to secure throttle cable.

11.Remove caps from fuel hose and injector pump fuel

inlet that were placed during engine removal to prevent

contamination. Connect fuel supply hose to injection

pump (Fig. 9). Secure hose with hose clamp.

12.Connect wire harness connectors to the following

engine components:

A. The engine run solenoid (Fig. 9).

B. The temperature sender (Fig. 10).

C. The alternator (Fig. 10).

D. The glow plug connection.

E. Wire harness connector to engine ground har-

ness.

F. The electric starter. Torque nut at starter B+ termi-

nal from

70 to 86 in--lb (7.9 to 9.7 N--m)

.

G. Low oil pressure switch located on alternator side

of engine (above electric starter).

13.Using notes taken during engine removal, secure

wires with cable ties in proper locations.

14.Install air cleaner assembly to the engine (see Air

Cleaner Installation in this section).

15.Install exhaust system to machine (see Exhaust Sys-

tem Installation in this section).

16.Connect coolant hoses to the radiator. Make sure ra-

diator draincock is closed. Fill radiator and reservoir with

coolant.

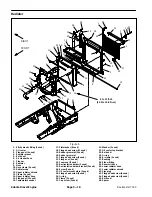

17.Check position of wires, fuel lines, hydraulic hoses

and cables for proper clearance with rotating, high tem-

perature and moving components.

18.Connect positive battery cable first and then nega-

tive battery cable. Secure battery cover to machine.

19.Check and adjust engine oil level as needed.

20.Check and adjust hydraulic oil level as needed.

21.Bleed fuel system.

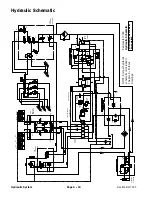

22.Operate hydraulic controls to properly fill hydraulic

system (see Charge Hydraulic System in the Service

and Repairs section of Chapter 4 -- Hydraulic Systems).

23.Install hood on the machine (see Hood Installation in

the Service and Repairs section of Chapter 7 -- Chas-

sis).

Kubota

Diesel

Engine

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...