Reelmaster 7000

Page 5 -- 9

Electrical System

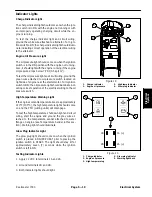

Verify Diagnostic Display Output Functions

The Diagnostic Display also has the ability to detect

which output solenoids or relays are energized by the

TEC controller(s). This is a quick way to determine if a

machine malfunction is electrical or hydraulic.

NOTE:

An open output (e.g. an unplugged connector or

a broken wire) cannot be detected with the Diagnostic

Display.

1. Park machine on a level surface, lower the cutting

units, stop the engine and engage the parking brake.

2. Remove plate in front of seat to allow access to wire

harness loop--back connector. Locate wire harness and

loop--back connector (Fig. 10). Carefully unplug loop--

back connector from harness connector.

3. Connect the Diagnostic Display connector to the har-

ness connector. Make sure correct overlay decal is posi-

tioned on the Diagnostic Display (Fig. 11).

4. Turn the ignition switch to the ON position.

NOTE:

The

red

text on the Diagnostic Display overlay

decal refers to input switches and the

green

text refers

to TEC outputs.

5. The “outputs displayed” LED, on lower right column

of the Diagnostic Display, should be illuminated. If “in-

puts displayed” LED is illuminated, press the toggle but-

ton on the Diagnostic Display to change the LED to

“outputs displayed”.

NOTE:

It may be necessary to toggle between “inputs

displayed” and “outputs displayed” several times to per-

form the following step. To change from inputs to out-

puts, press toggle button once. This may be done as

often as required.

Do not press and hold toggle but-

ton

.

6. Sit on seat and attempt to operate the desired func-

tion of the machine. The appropriate output LED’s

should illuminate on the Diagnostic Display to indicate

that the TEC controller is turning on that function. The

GLOW PLUGS, HI RANGE and OK RUN outputs can be

checked with the ignition switch in the ON position and

the engine not running. For testing of the solenoid out-

puts (e.g. PTO 1, ENABLE, REAR REELS), the engine

must be running.

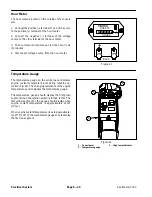

A. If the correct output LED’s do not illuminate, verify

that the required input switches are in the necessary

positions to allow that function to occur.

B. If the output LED’s are on as specified, but the

machine does not function properly, suspect a failed

electrical component, an open in the tested circuit or

a non-electrical problem (e.g. hydraulic component

problem). Repair as necessary.

C. If each input switch is in the correct position and

functioning correctly, but the output LED’s are not

correctly illuminated, this indicates a TEC controller

problem. If this occurs, contact your Toro Distributor

for assistance.

7. After output functions testing is complete, discon-

nect the Diagnostic Display connector from the harness

connector and plug loop--back connector into wire har-

ness. Secure access plate to frame.

1. Wire harness connector

2. Loop--back connector

3. TEC controller

Figure 10

1

2

3

Figure 11

TEC

OVERLAY

Electrical System

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...