Reelmaster 7000

Hydraulic System

Page 4 -- 75

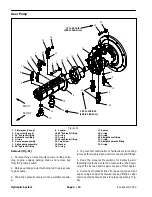

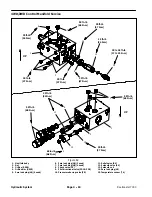

7. Support gear pump assembly to prevent it from fal-

ling.

8. Remove two (2) cap screws and washers securing

gear pump to piston pump. Remove gear pump, coupler

(item 9), spacer (item 17) and O--rings (item 16) from

machine.

9. If hydraulic fittings are to be removed from gear

pump, mark fitting orientation to allow correct assembly.

Remove fittings from pump and discard O--rings.

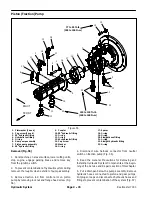

Installation (Fig. 51)

1. If fittings were removed from gear pump, lubricate

and place new O--rings onto fittings. Install fittings into

pump ports using marks made during the removal pro-

cess to properly orientate fittings. Tighten fittings (see

Hydraulic Fitting Installation in the General Information

section of this chapter).

2. Lubricate new O--rings (item 16) with clean hydraulic

oil. Position O--rings on gear pump and pump spacer

flanges.

3. Slide coupler (item 9) onto the piston pump output

shaft.

4. Position pump spacer (item 17) to gear pump. Align

gear teeth and slide gear pump input shaft into coupler.

Secure gear pump to piston pump with two (2) cap

screws and flat washers.

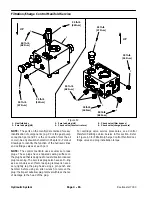

5. Remove caps and plugs from hydraulic hoses and

fittings. Install hoses to gear pump (see Hydraulic Hose

and Tube Installation in the General Information section

of this chapter).

6. Replace hydraulic filter and fill hydraulic reservoir

with new hydraulic oil.

7. Disconnect engine run solenoid electrical connector

to prevent engine from starting. Prime the hydraulic

pump by turning the ignition key switch to start and

cranking the engine for ten (10) seconds. Let starter cool

and then repeat cranking procedure again.

8. Connect engine run solenoid electrical connector,

start the engine and check for proper operation.

9. Properly fill hydraulic system (see Charge Hydraulic

System in this section).

10.Stop engine and check for hydraulic oil leaks. Check

hydraulic reservoir oil level.

11.Lower and secure seat.

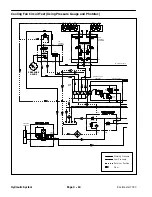

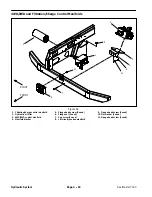

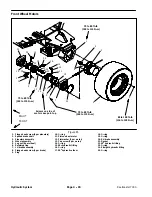

1. Supply hose to mow manifold P1 port

2. Supply hose to mow manifold P2 port

3. Supply hose to fan manifold P2 port

4. Supply hose to fan manifold P1 port

5. Suction hose from filter manifold

6. Suction hose from reservoir

7. Supply hose for charge circuit

Figure 52

4

5

1

2

3

6

7

FRONT

RIGHT

Hydraulic System

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...