Reelmaster 7000

Page 5 -- 22

Electrical System

Cutting Unit Lift Switch

The cutting unit lift switch is used as an input for the TEC

controller to raise or lower the cutting units. When the lift

switch paddle is depressed and held, the cutting units

will lower. When the lift switch paddle is raised and held,

the cutting units will raise. The cutting units will remain

in position when the switch is released. The lift switch is

located on the console arm (Fig. 25).

NOTE:

To lower the cutting units, the mow speed limiter

has to be in mow range (4WD). Also, to raise or lower the

cutting units, the seat has to be occupied.

Testing

1. Before disconnecting the lift switch for testing, the

switch and its circuit wiring should be tested as a TEC

input with the Diagnostic Display (see Diagnostic Dis-

play in the Troubleshooting section of this chapter). If the

Diagnostic Display verifies that the lift switch and circuit

wiring

are

functioning correctly, no further switch testing

is necessary. If, however, the Display determines that

the lift switch and circuit wiring

are not

functioning cor-

rectly, proceed with test.

2. Make sure ignition switch is OFF. Remove key from

ignition switch.

3. Disassemble console arm to gain access to cutting

unit lift switch (see Console Arm Disassembly in the Ser-

vice and Repairs section of Chapter 7 -- Chassis).

4. Disconnect harness electrical connector from the lift

switch.

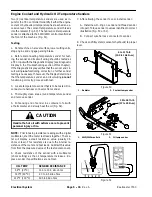

5. The switch terminals are marked as shown in Figure

27. The circuit logic of the lift switch is shown in the chart

below. With the use of a multimeter (ohms setting), the

switch functions may be tested to determine whether

continuity exists between the various terminals for each

position. Verify continuity between switch terminals. Re-

place switch if testing identifies a faulty switch.

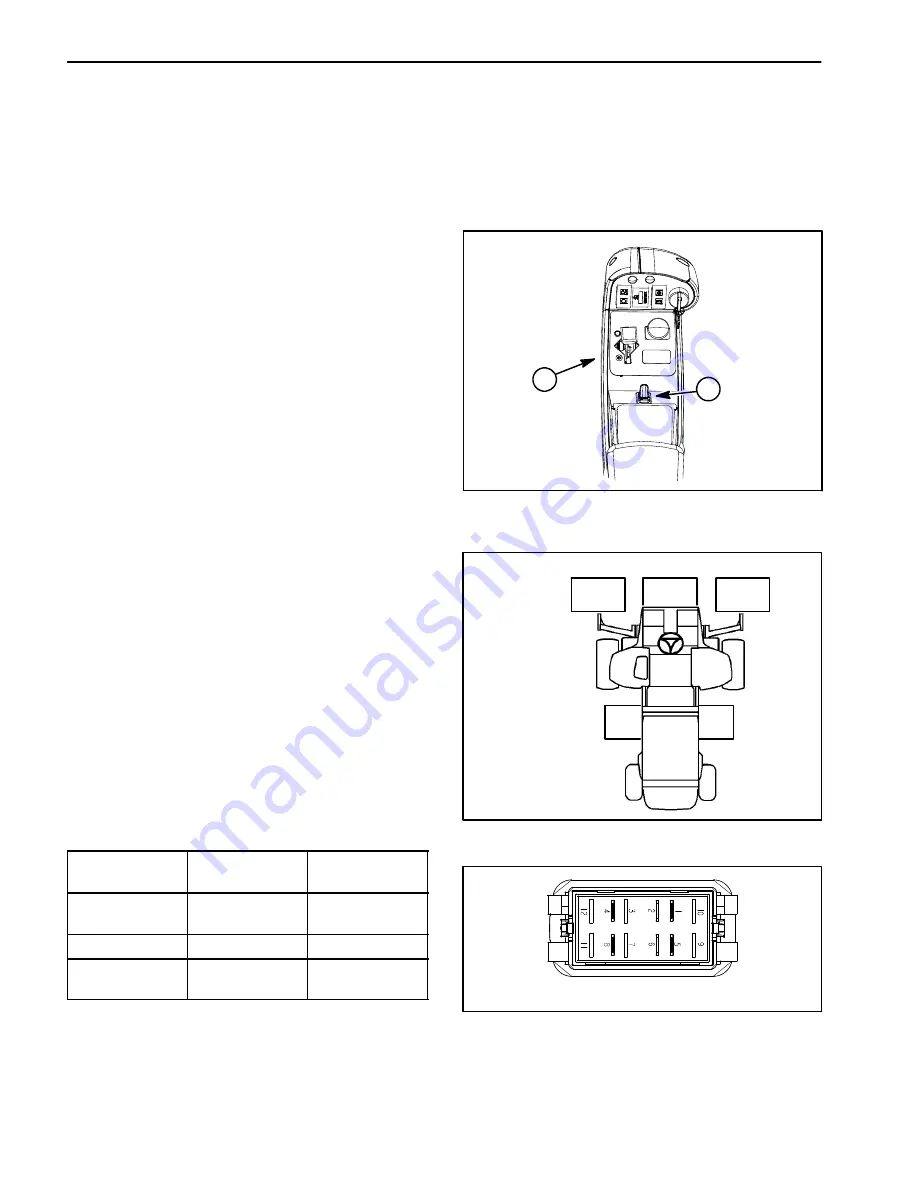

SWITCH

POSITION

CLOSED

CIRCUITS

OPEN

CIRCUITS

LOWER

2 + 1

6 + 5

2 + 4

6 + 8

NEUTRAL

NONE

ALL

RAISE

2 + 4

6 + 8

2 + 1

6 + 5

6. If lift switch tests correctly and circuit problem still ex-

ists, check wire harness (see Electrical Schematics and

Wire Harness Drawings in Chapter 9 -- Foldout Draw-

ings).

7. After testing is completed, connect wire harness

connector to the lift switch.

8. Assemble console arm (see Console Arm Assembly

in the Service and Repairs section of Chapter 7 -- Chas-

sis).

1. Console arm

2. Lift switch

Figure 25

1

2

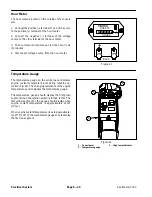

Figure 26

#4

#1

#5

#3

#2

CUTTING

UNIT

LOCATIONS

Figure 27

BACK OF SWITCH

NOTE:

Lift switch terminals 5, 6 and 8 are not used on

Reelmaster 7000 machines.

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...