Reelmaster 7000

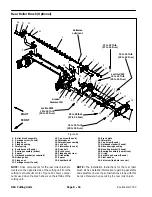

DPA Cutting Units

Page 8 -- 39

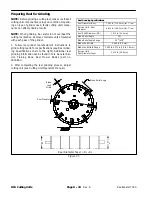

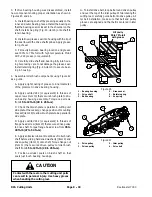

5. Check alignment of pulleys with a straight edge

placed along the outer face of the driven pulley (Fig. 48).

The outer faces of the driven and drive pulleys (not the

idler pulley) should be in line within 0.030” (0.76 mm). If

necessary to align pulleys, remove driven pulley from

brush shaft and add or remove hardened washer(s)

(item 9) until drive and driven pulleys are aligned within

0.030” (0.76 mm).

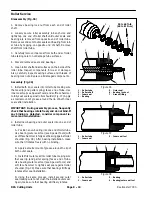

6. Check that roller brush is parallel to rear roller with

0.060” (1.5 mm) clearance to light contact with roller

(Fig. 49). If contact is incorrect, brush operation will be

adversely affected.

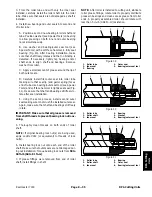

7. Lubricate grease fittings on brush housings until

grease purges past inboard seals. Wipe excess grease

from seals and fittings.

CAUTION

Contact with the reel, bedknife or other cutting

unit parts can result in personal injury. Use

heavy gloves when handling the cutting reel.

1. Drive pulley

2. Driven pulley

3. Straight edge

Figure 48

1

2

3

CHECK

ALIGNMENT

1. Rear roller brush

2. Rear roller

3. Light contact

Figure 49

2

1

3

DP

A

C

utting

Units

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

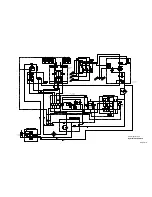

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

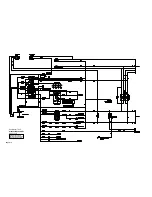

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...