Reelmaster 7000

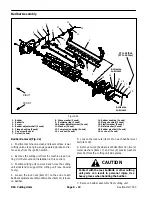

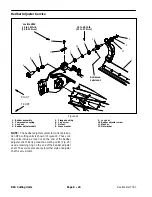

DPA Cutting Units

Page 8 -- 9

Factor

Possible Problem/Correction

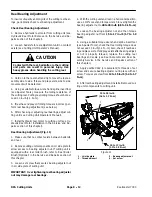

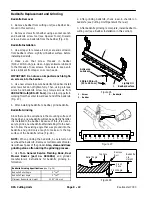

Reel and bedknife sharpness

A reel and/or bedknife that has rounded cutting edges

or “rifling” (grooved or wavy appearance)

cannot

be

corrected by tightening the bedknife to reel contact.

Grind cutting reel to remove taper and/or rifling. Grind

bedknife to sharpen and/or remove rifling.

The most common cause of rifling is bedknife to reel

contact that is too tight.

Dull cutting edges must be corrected by grinding the

bedknife and cutting reel (see Preparing Reel for

Grinding in the Service and Repairs section of this

chapter).

A new bedknife must be ground flat (within 0.002”)

after installation to the bedbar. Backlapping may

be required to properly mate the reel and bedknife

after installation into the cutting unit.

NOTE:

On cutting units equipped with optional

bedknifes, slightly dull cutting edges may be corrected

by backlapping (see Backlapping in the Service and

Repairs section of this chapter).

Rear roller adjustment

Adjust the rear roller brackets to correct position

depending on the height--of--cut range desired.

See Rear Roller Adjustment in the Cutting Unit

Operator’s Manual.

Height--of--cut

“Effective” or actual height--of--cut depends on the

cutting unit weight and turf conditions. Effective

height--of--cut will be different from the bench set

height--of--cut.

See Height--of--Cut Adjustment in the Cutting Unit

Operator’s Manual.

Proper bedknife selection for height--of--cut desired

If the bedknife is incorrect for effective height--of--cut,

poor quality of cut will result.

See Cutting Unit Operator’s Manual for bedknife

options.

Stability of bedbar

Make sure bedbar pivot bolts are seated securely.

Check condition of the bushings in the side plates.

See Bedbar Removal and Installation in the Service

and Repairs section of this chapter.

Number of reel blades

Use correct number of reel blades for clip frequency

and optimum height--of--cut range.

Cutting unit alignment and carrier frame ground

following

Check carrier frames and lift arms for damage, binding

conditions or bushing wear. Repair if necessary.

DP

A

C

utting

Units

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...