Reelmaster 7000

Hydraulic System

Page 4 -- 4

General Information

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for your Reelmaster machine. Refer to that

publication for additional information when servicing the

machine.

Towing Traction Unit

IMPORTANT: If towing limits are exceeded, severe

damage to the piston pump may occur.

If it becomes necessary to tow (or push) the machine,

tow (or push) in a

forward direction only

, at a speed

below 3 mph (4.8 kph)

and for a distance

less than 1/4

mile (0.4 km)

. The piston (traction) pump is equipped

with a bypass valve that needs to be turned 90

o

for tow-

ing (Fig. 1). Do not turn bypass valve when engine is run-

ning.

See Traction Unit Operator’s Manual for additional tow-

ing procedures.

IMPORTANT: If the machine must be pushed or

towed in a reverse direction, the check valve in the

4WD/2WD control manifold must be bypassed. To

bypass this check valve, connect a hydraulic hose

between the reverse traction pressure test port and

the 4WD/2WD control manifold test port (G). Toro

part numbers 95--8843 (hydraulic hose), 95--0985

(coupler fitting) (2 required) and 340--77 (hydraulic

fitting) (2 required) are needed for this connection.

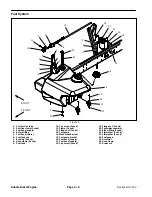

1. Bypass valve location

Figure 1

1

Check Hydraulic Fluid

The Reelmaster 7000 hydraulic systems are designed

to operate on anti--wear hydraulic fluid. The reservoir

holds approximately 8.25 U.S. gallons (31.3 liters) of hy-

draulic fluid.

Check level of hydraulic fluid daily.

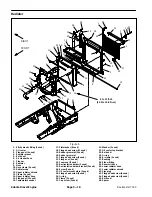

Figure 2

1. Hydraulic reservoir

2. Reservoir cap

1

2

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...