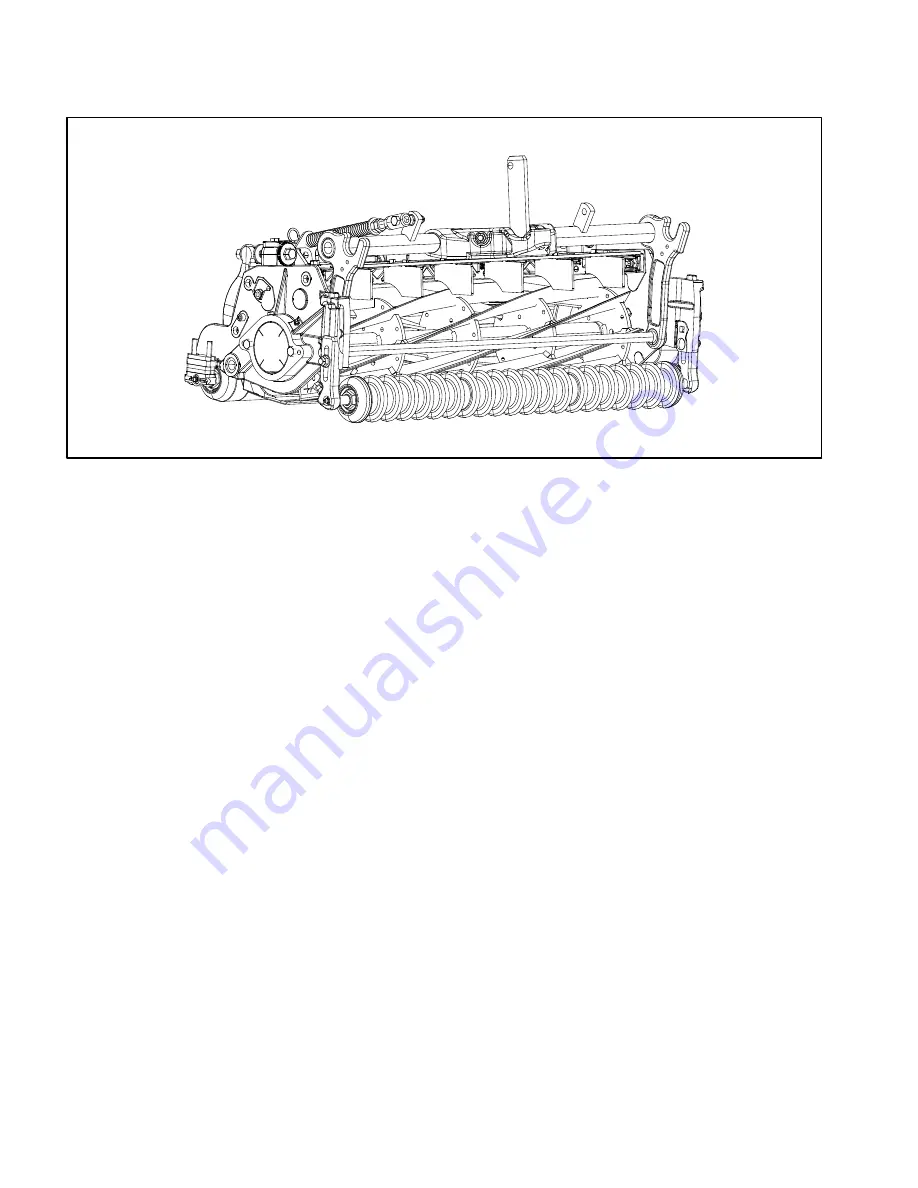

Reelmaster 7000

DPA Cutting Units

Page 8 -- 2

Specifications

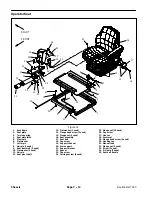

Figure 1

Frame Construction:

Precision machined die cast alu-

minum cross member with two (2) bolt--on cast ductile

iron side plates.

Reel Construction:

Reels are 27 inches (69 cm) in

length and 7 inch (18 cm) in diameter. High strength, low

alloy steel blades are thru hardened and impact resis-

tant. Reels are available in 8 and 11 blade configura-

tions. Optional 32 inch (81 cm), 8 blade reels are

available for the rear cutting unit positions.

Reel Bearings:

Two (2) double row, self--aligning ball

bearings support the reel shaft with inboard seal for

protection. Reel bearing adjustment is maintained by an

adjuster nut in the left side plate of the cutting unit.

Reel Drive:

The reel weldment shaft is a 1 5/16 inch

(33.3 mm) diameter tube with drive inserts threaded into

both ends. The reel drive inserts have an internal nine

(9) tooth spline.

Height--of--Cut (HOC):

Cutting height is adjusted on

the front roller by two (2) vertical screws. Effective HOC

may vary depending on turf conditions, type of bedknife,

roller type and installed attachments.

Bedknife:

Replaceable, single edged, high carbon

steel bedknife is fastened to a machined cast iron bed-

bar with screws. Optional bedknifes are available.

Bedknife Adjustment:

Dual screw adjustment to the

reel; detents corresponding to 0.0009 inch (0.023 mm)

bedknife movement for each indexed position.

Front and Rear Rollers:

Greaseable through--shaft

front and rear rollers are used with these cutting units.

All rollers use the same heavy duty ball bearings.

Counterbalance Weight:

A cast iron weight mounted

opposite to the hydraulic drive motor balances the cut-

ting unit.

Cutting Unit Weight:

27” Reel, 8 Blade

170 lb. (77 kg)

27” Reel, 11 Blade

175 lb. (79 kg)

32” Reel, 8 Blade (optional)

191 lb. (87 kg)

Options:

Refer to Cutting Unit Operator’s Manual for available op-

tions for your Reelmaster DPA cutting unit.

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...