Reelmaster 7000

DPA Cutting Units

Page 8 -- 33

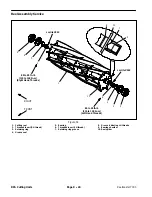

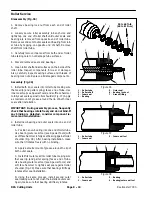

Rear Roller

Removal (Fig. 35)

1. Position machine on a clean and level surface, lower

cutting units, stop engine, engage parking brake and re-

move key from the ignition switch.

2. Remove the cutting unit from the machine and place

on a level working surface. Place support blocks under

bedbar to raise rear roller from work surface.

3. Loosen two (2) flange nuts that secure the rear roller

shaft to each rear roller bracket.

4. On one of the rear roller brackets:

NOTE:

On cutting units equipped with optional High

Height of Cut Kit, there will be additional roller shims

installed between rear roller bracket and cutting unit

side plate.

A. Remove flange nuts and carriage screws that se-

cure rear roller bracket and roller shims to the cutting

unit side plate.

B. Remove the roller bracket and roller shims from

the rear roller and cutting unit.

5. Slide the rear roller assembly from the remaining

rear roller bracket on the cutting unit.

6. If necessary, remove the second rear roller bracket

and roller shims from the cutting unit.

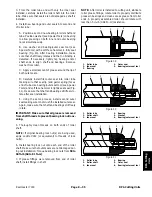

Installation (Fig. 35)

1. Place cutting unit on a level working surface.

NOTE:

Refer to Cutting Unit Operator’s Manual for

number of roller shims required for various height of cut

settings.

NOTE:

A 0.010” shim (part number 107--4001) is avail-

able to allow for leveling of the rear roller (see Leveling

Rear Roller in the Set--up and Adjustments section of

this chapter). If necessary, this shim would be used on

one side of the rear roller and should be installed be-

tween the rear roller bracket and roller shim.

2. If both rear roller brackets were removed from cutting

unit side plate, position brackets and roller shims to one

of the side plates. Install two (2) carriage screws and

flange nuts to retain bracket in position. Do not fully tight-

en flange nuts.

1. Rear roller assembly

2. Rear roller bracket

3. Carriage screw

4. Flange nut

5. Roller shim

6. 0.010” shim (if needed)

Figure 35

1

2

3

4

5

6

3. Slide rear roller shaft into the rear roller bracket at-

tached to the cutting unit. Slide second rear roller brack-

et onto the other end of roller shaft. Secure second roller

bracket and shims to cutting unit side plate with two (2)

carriage screws and flange nuts. Do not fully tighten

flange nuts.

4. Center rear roller to the cutting reel and secure in

place by tightening four (4) flange nuts.

5. Lubricate rear roller.

6. Adjust cutting unit (see Cutting Unit Operator’s

Manual).

DP

A

C

utting

Units

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...