Reelmaster 7000

Page 5 -- 2

Electrical System

General Information

Operator’s Manual

The Operator’s Manual provides information regarding

the operation, general maintenance and maintenance

intervals for your Reelmaster machine. Refer to the Op-

erator’s Manual for additional information when servic-

ing the machine.

Toro Electronic Controller (TEC)

Reelmaster 7000 machines use a single Toro Electronic

Controller (TEC) to manage machine electrical func-

tions.

The controller is microprocessor controlled that senses

the condition of various machine switches (inputs) and

directs electrical power to control appropriate machine

functions (outputs) based on the state of the inputs. The

status of inputs to the controllers as well as outputs from

the controllers can be checked with the Diagnostic Dis-

play (see Special Tools).

Because of the solid state circuitry built into the Toro

Electronic Controller (TEC), there is no method to test

it directly. The TEC may be damaged if an attempt is

made to test it with an electrical test device, such as a

digital multimeter.

IMPORTANT: Before performing any welding on the

machine, disconnect the battery cables from the

battery, disconnect the wire harness connectors

from the Toro Electronic Controller(s) and discon-

nect the terminal connector from the alternator to

prevent damage to the machine electrical system.

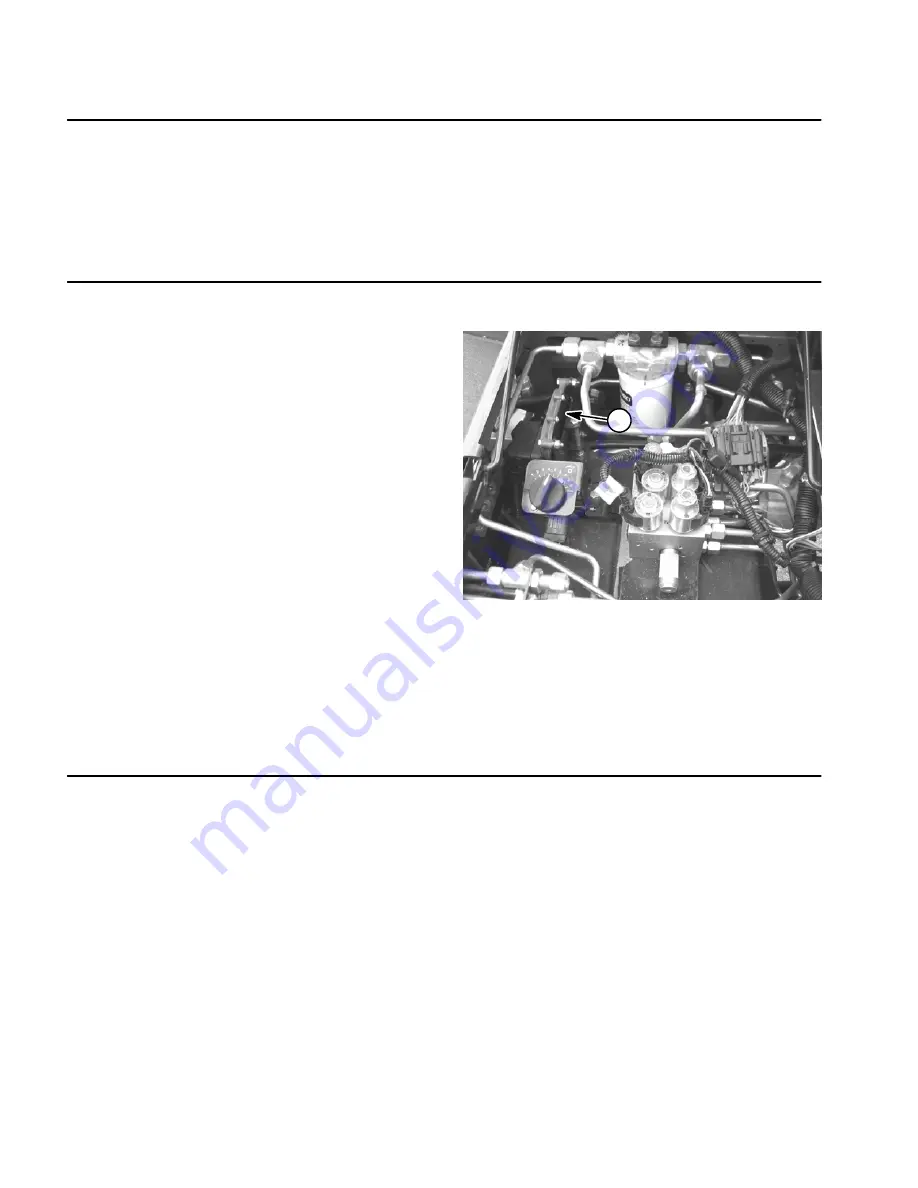

Figure 1

1

1. Toro Electronic Controller

CAN--bus Communications

The TEC controller used on the Reelmaster 7000 can

communicate with other electrical components on a

CAN--bus communication system. The CAN--bus sys-

tem reduces the number of electrical components and

connections used on the machine and allows the num-

ber of wires in the wire harness to be reduced.

CAN identifies the Controller Area Network that is used

on the Reelmaster. Two (2) specially designed, twisted

cables form the bus. These wires provide the data path-

ways between machine components. The engineering

term for these two (2) cables are CAN--high and CAN--

low. At the ends of the twisted pair of bus cables are 120

ohm termination resistors.

Each of the components that is controlled by the CAN--

bus link only needs four (4) wires to operate and commu-

nicate to the system: CAN--high, CAN--low, B+ (power)

and ground.

IMPORTANT: The termination resistors at the ends

of the bus cables are required for proper electrical

system operation.

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...