Reelmaster 7000

Page 5 -- 37

Electrical System

Fuel Pump

The fuel pump is energized by the TEC controller when

the ignition switch is either in the START or ON position.

The fuel pump is attached to the left side frame rail.

IMPORTANT: When testing fuel pump, make sure

that pump is not operated without fuel.

Fuel Pump Capacity Test

1. Park machine on a level surface, lower cutting units,

stop engine and engage parking brake. Remove key

from ignition switch.

2. Raise and support hood.

3. Remove 20A fuse (F1--1) (Fig. 54) from fuse block to

prevent the engine from cranking.

4. Make sure fuel hoses attached to the fuel pump are

free of obstructions.

5. Disconnect fuel pump discharge hose from the fuel/

water separator inlet fitting (Fig. 53).

6. Place disconnected fuel hose (pump discharge) into

a large, graduated cylinder sufficient enough to collect

1 quart (0.95 liter).

7. Collect fuel in the graduated cylinder by turning igni-

tion switch to the ON position. Allow pump to run for fif-

teen (15) seconds, then turn switch to OFF.

8. The amount of fuel collected in the graduated cylin-

der should be approximately 16 fl oz (475 ml) after fif-

teen (15) seconds.

9. Replace fuel pump if necessary.

10.Install fuel hose to the fuel/water separator. Secure

hose with hose clamp.

11.Install 20A fuse into fuse block.

12.Bleed the fuel system.

13.Lower and secure hood.

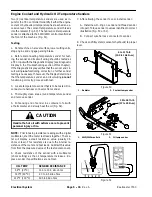

1. Fuel/water separator

2. Pump discharge hose

3. Inlet fitting

Figure 53

2

1

3

Figure 54

FRONT

F3

F2

F1

2A

7.5A

7.5A

7.5A

10A

10A

10A

10A

20A

OP

TION

OP

TION

OP

TION

M1 (60A)

M2 (option)

Fuel Pump Specifications

Pump Capacity

64 fl oz/min (1.9 l/min)

Pressure

7 PSI (48.3 kPa)

Current Draw

2.0 amp

Electrical System

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...