Reelmaster 7000

Page 7 -- 13

Chassis

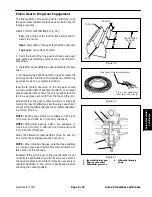

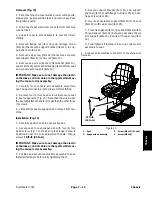

Removal (Fig. 12)

1. Park machine on a level surface, lower cutting units,

stop engine, apply parking brake and remove key from

the ignition switch.

2. Disconnect seat electrical connector from machine

wire harness.

3. Support console arm assembly to prevent it from

shifting.

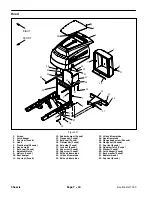

4. Remove flange nut (item 25) and carriage screw

(item 24) that secure support bracket (item 21) to sup-

port channel (item 19).

5. Remove cap screw (item 26) that secures console

arm support (item 20) to hex nut (item 27).

6. Remove cap screw (item 23), flat washer (item 10),

spacer (item 22) and seat belt buckle (item 35) from seat

and console arm support (item 20).

IMPORTANT: Make sure to not damage the electri-

cal harness, control cable or other parts while mov-

ing the console arm assembly.

7. Carefully move console arm assembly away from

seat. Support console arm to prevent it from falling.

8. Remove four (4) torx head screws that secure seat

to seat suspension (Fig. 13). Note that the screw near

the seat adjustment handle is longer than the other three

(3) screws.

9. Lift seat from seat suspension and remove from ma-

chine.

Installation (Fig. 12)

1. Carefully position seat to seat suspension.

2. Secure seat to seat suspension with four (4) torx

head screws (Fig. 13). Make sure that longer screw is

positioned near the seat adjustment handle. Torque

screws

18 ft--lb (25 N--m)

.

IMPORTANT: Make sure to not damage the electri-

cal harness, control cable or other parts while mov-

ing the console arm assembly.

3. Position and secure console arm assembly to seat.

Install all fasteners before fully tightening them.

A. Secure support bracket (item 21) and support

channel (item 19) with flange nut (item 25) and car-

riage screw (item 24).

B. Secure console arm support (item 20) to hex nut

(item 27) with cap screw (item 26).

C. Place flat washer (item 10), seat belt buckle (item

35) and spacer (item 22) between seat and console

arm support (item 20). Secure with cap screw (item

23).

D. Fully tighten all fasteners to secure console arm

assembly to seat.

4. Connect seat electrical connector to machine wire

harness.

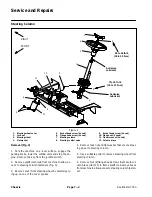

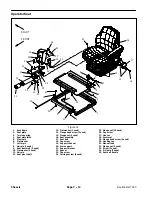

1. Seat

2. Suspension assembly

3. Screw (M8x12) (3 used)

4. Screw (M8x16)

Figure 13

2

3

1

4

18 ft--lb

(25 N--m)

Chassis

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...