Reelmaster 7000

Hydraulic System

Page 4 -- 51

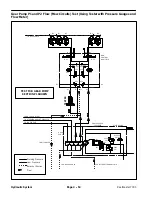

The mow circuit relief pressure test should be performed

to make sure that the mow circuit relief pressures are

correct.

Procedure for Mow Circuit Relief Pressure Test

1. Make sure hydraulic oil is at normal operating tem-

perature by operating the machine for approximately ten

(10) minutes. Make sure the hydraulic tank is full.

2. Park machine on a level surface with the cutting units

lowered and off. Make sure engine is off and the parking

brake is engaged. Also, make sure that the backlap lev-

ers on the mow control manifold are in the mow position

(F on the manifold).

CAUTION

Prevent personal injury and/or damage to equip-

ment. Read all WARNINGS, CAUTIONS and Pre-

cautions for Hydraulic Testing at the beginning

of this section.

3. Determine mow manifold relief pressure to be

tested:

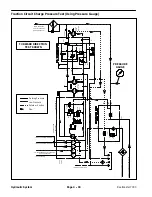

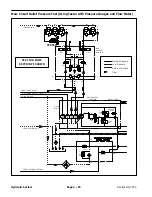

A. For pump section (P1), mow manifold relief is

tested at the forward direction supply hose (front

hose) to the cutting unit #4 motor (Fig. 39).

B. For pump section (P2), mow manifold relief is

tested at the forward direction supply hose (front

hose) to the cutting unit #2 motor (Fig. 39).

4. Thoroughly clean junction of appropriate hydraulic

supply hose and cutting unit motor fitting. Disconnect

the supply hydraulic hose from the motor.

IMPORTANT: Make sure that the oil flow indicator

arrow on the tester is showing that the oil will flow

from the disconnected hose, through the tester and

into the hydraulic motor.

5. Install tester with pressure gauge and flow meter in

series with the disconnected hose and front motor fit-

ting.

6. Make sure the flow control valve on the tester is fully

open.

7. Start engine and run at low idle speed. Check for hy-

draulic leakage and correct before proceeding with test.

8. Move throttle to high idle speed

(2850 RPM)

. Make

sure that mow speed limiter is in the mow (4WD) posi-

tion. Release parking brake.

CAUTION

Cutting reel blades will rotate when lowered with

PTO switch in ON position. Keep away from cut-

ting units during test to prevent personal injury

from rotating reel blades. Do not stand in front of

the machine during test.

9. With seat occupied, engage the cutting units.

10.Have a second person carefully watch tester pres-

sure gauge while slowly closing the flow control valve on

tester.

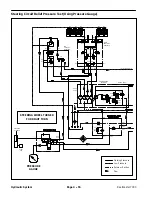

11.As the relief valve lifts, system pressure should be

from

2800 to 3200 PSI (193 to 220 bar)

.

12.After noting the relief pressure, open the tester flow

control valve, disengage cutting units and stop the en-

gine. Record test results.

13.If specification is

not

met, clean or adjust relief valve

(RV1 or RV2) in the mow control manifold. See Adjust

Control Manifold Relief Valves in the Adjustments sec-

tion of this chapter for valve adjustment procedure. Re-

check relief valve pressure setting after adjustment.

14.After testing is complete, disconnect tester from cut-

ting unit motor and hose. Connect hydraulic hose to mo-

tor.

Figure 39

#4

#1

#5

CUTTING

UNIT

LOCATIONS

#2

#3

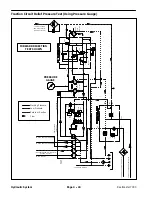

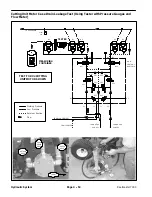

Figure 40

RETURN

HOSE

SUPPLY

HOSE

FRONT

Hydraulic System

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...