Reelmaster 7000

DPA Cutting Units

Page 8 -- 21

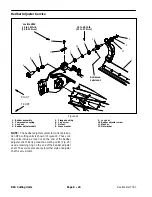

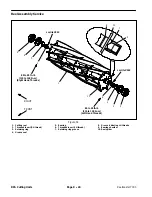

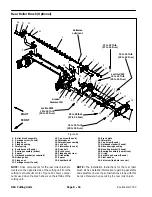

Removal (Fig. 24)

1. Remove lock nut (item 3), compression spring (item

2) and washer (item 11) from bedbar adjuster screw

(item 10).

2. Remove bedbar (see Bedbar Removal in this sec-

tion).

NOTE:

Inside threads in bedbar adjuster shaft (item 4)

are left--hand threads.

3. Unscrew bedbar adjuster screw (item 10) from the

bedbar adjuster shaft (item 4).

4. Remove adjuster shaft from cutting unit frame:

A. On current production cutting units (Fig. 24), re-

move lock nut and flat washer from adjuster shaft.

Slide adjuster shaft and wave washer from cutting

unit frame.

B. On early production cutting units (Fig. 25), re-

move retaining ring and wave washer from adjuster

shaft. Slide adjuster shaft from cutting unit frame.

5. Inspect flange bushings (item 5) in cutting unit frame

and remove if necessary.

6. If detent (item 7) is damaged, remove it from cutting

unit side plate by removing the cap screw (item 6).

Installation (Fig. 24)

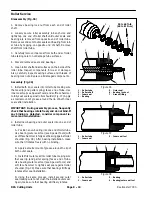

1. If detent (item 7) was removed, apply Loctite #242

(or equivalent) to threads of cap screw (item 6) and se-

cure detent to cutting unit side plate with cap screw.

Torque cap screw from

14 to 16 ft--lb (19 to 21 N--m)

.

2. If flange bushings (item 5) were removed, apply anti-

seize lubricant to bore of cutting unit frame. Align key on

bushing to slot in frame and install bushings into frame.

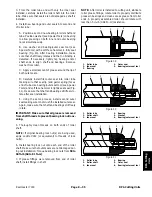

3. Install adjuster shaft to cutting unit frame:

A. On current production cutting units (Fig. 24), slide

wave washer onto adjuster shaft and then slide ad-

juster shaft into flange bushings in cutting unit frame.

Secure adjuster shaft with flat washer and lock nut.

Tighten lock nut to shoulder of adjuster shaft and

then torque lock nut from

15 to 20 ft--lb (21 to 27

N--m)

.

B. On early production cutting units (Fig. 25), slide

bedbar adjuster shaft into flange bushings in cutting

unit frame. Secure adjuster shaft with wave washer

and retaining ring.

NOTE:

Inside threads in bedbar adjuster shaft (item 4)

are left--hand threads.

4. Apply antiseize lubricant to threads of bedbar adjust-

er screw (item 10) that fit into adjuster shaft. Thread bed-

bar adjuster screw into adjuster shaft (item 4).

5. Install bedbar (see Bedbar Installation in this sec-

tion).

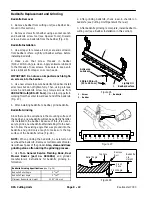

6. Install washer (item 11), compression spring (item 2)

and lock nut (item 3) onto adjuster screw. Tighten the

lock nut on each bedbar adjuster assembly until the

compression spring is fully compressed, then loosen

lock nut 1/2 turn.

7. Adjust cutting unit (see Cutting Unit Operator’s

Manual).

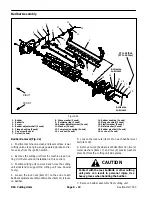

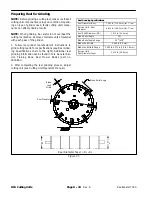

1. Bedbar adjuster screw

2. Retaining ring

3. Wave washer

4. Flange bushing

5. Cap screw

6. Detent

7. Bedbar adjuster shaft

Figure 25

4

6

7

5

4

3

2

1

Antiseize

Lubricant

14 to 16 ft--lb

(19 to 21 N--m)

Loctite #242

DP

A

C

utting

Units

Summary of Contents for Reelmaster 7000

Page 2: ...Reelmaster 7000 This page is intentionally blank ...

Page 4: ...Reelmaster 7000 This page is intentionally blank ...

Page 10: ...Reelmaster 7000 Page 1 6 Safety This page is intentionally blank ...

Page 12: ...0 09375 Reelmaster 7000 Page 2 2 Product Records and Maintenance Equivalents and Conversions ...

Page 34: ...Reelmaster 7000 Page 3 18 Kubota Diesel Engine This page is intentionally blank ...

Page 36: ...Reelmaster 7000 Hydraulic System Page 4 2 This page is intentionally blank ...

Page 45: ...Reelmaster 7000 Hydraulic System Page 4 11 This page is intentionally blank Hydraulic System ...

Page 115: ...Reelmaster 7000 Hydraulic System Page 4 81 This page is intentionally blank Hydraulic System ...

Page 131: ...Reelmaster 7000 Hydraulic System Page 4 97 This page is intentionally blank Hydraulic System ...

Page 139: ...Reelmaster 7000 Hydraulic System Page 4 105 This page is intentionally blank Hydraulic System ...

Page 147: ...Reelmaster 7000 Hydraulic System Page 4 113 This page is intentionally blank Hydraulic System ...

Page 151: ...Reelmaster 7000 Hydraulic System Page 4 117 This page is intentionally blank Hydraulic System ...

Page 168: ...Reelmaster 7000 Hydraulic System Page 4 134 This page is intentionally blank ...

Page 214: ...Reelmaster 7000 Page 5 46 Electrical System This page is intentionally blank ...

Page 247: ...Reelmaster 7000 Page 7 3 Chassis This page is intentionally blank Chassis ...

Page 264: ...Reelmaster 7000 Page 7 20 Chassis This page is intentionally blank ...

Page 271: ...Reelmaster 7000 DPA Cutting Units Page 8 7 This page is intentionally blank DPA Cutting Units ...

Page 304: ...Reelmaster 7000 DPA Cutting Units Page 8 40 This page is intentionally blank ...

Page 306: ...Reelmaster 7000 Foldout Drawings Page 9 2 This page is intentionally blank ...

Page 310: ...Page 9 6 Reelmaster 7000 Main Wire Harness ...

Page 312: ...Page 9 8 Reelmaster 7000 Seat and Console Wire Harness ...

Page 314: ...Page 9 10 Reelmaster 7000 Power Center Wire Harness ...