SECTION 4

4-32

1-/ 2-Cylinder

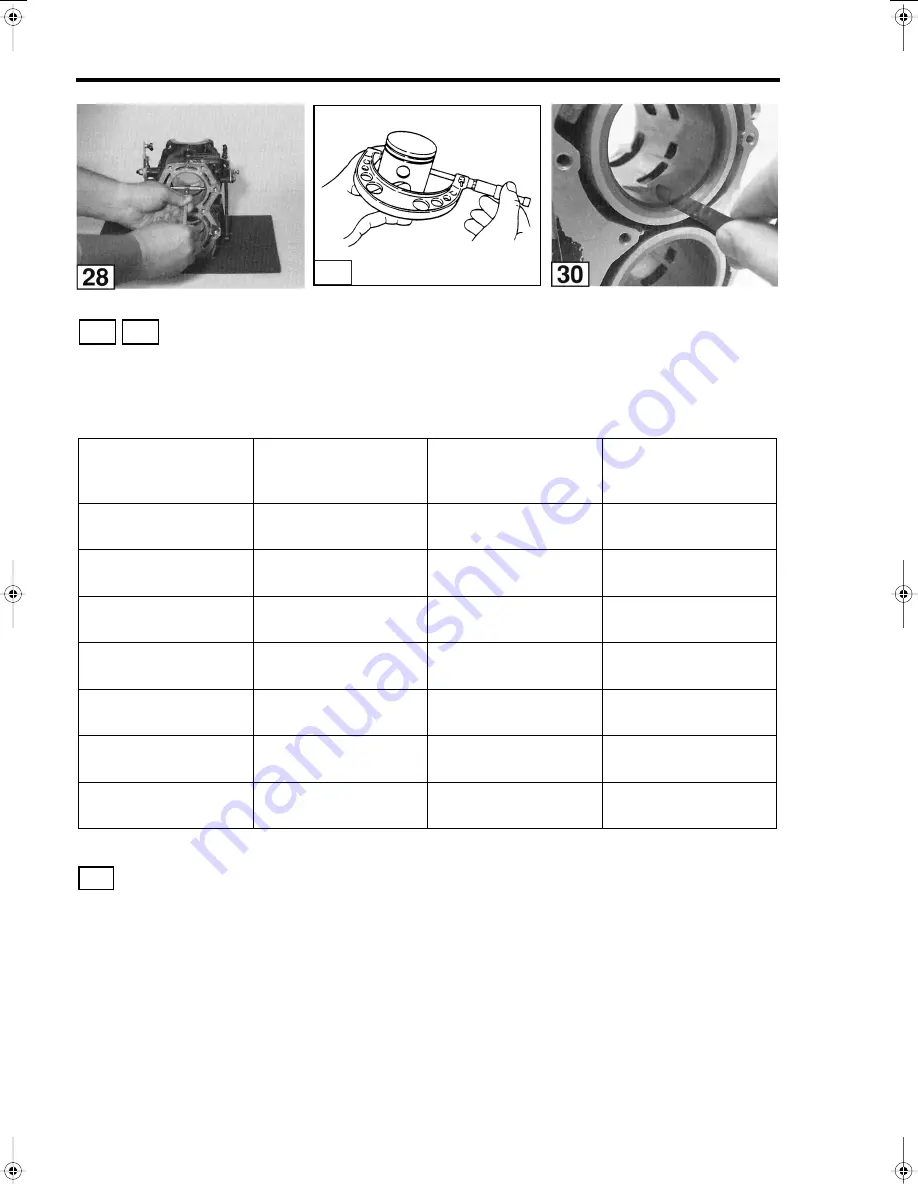

7. Measure and record the diameter of each cylinder

bore and the outside diameter of its respective piston.

Subtract the values to calculate the piston clearances. lf any bore

diameter or piston clearance exceeds the specified limit, the cylinder

must be professionally bored oversize for use with an oversize piston.

8. Complete the following inspection for new or used piston

ring sets. Inspect each ring separately:

• Place ring in its respective cylinder bore.

• Use a piston to square the ring in the bore.

• Use the thickness gauge set (Part No. 353-72251-0) to measure

the ring end gap.

Model

Standard

Bore Diameter

in [mm]

Standard

Piston Clearance

in [mm]

Repair Limit

Piston Clearance

in [mm]

2.5 / 3.5

1.85 [47]

0.0024 - 0.0035

[0.06 - 0.09]

0.006 or over

[0.15 or over]

5

2.16 [55]

0.008 - 0.020

[0.02 - 0.05]

0.006 or over

[0.15 or over]

8 / 9.8

1.97 [50]

0.008 - 0.020

[0.02 - 0.05]

0.006 or over

[0.15 or over]

9.9 / 15

2.16 [55]

0.0020 - 0.0035

[0.05 - 0.09]

0.006 or over

[0.15 or over]

18

2.36 [60]

0.0020 - 0.0035

[0.05 - 0.09]

0.006 or over

[0.15 or over]

25 / 30

2.68 [68]

0.0024 - 0.0039

[0.06 - 0.10]

0.006 or over

[0.15 or over]

40

2.76 [70]

0.0020 - 0.0039

[0.05 - 0.10]

0.006 or over

[0.15 or over]

28 29

30

T2027

T2028

29

T1235

Summary of Contents for 2 Stroke Cylinder Series

Page 1: ...PNo 003 21035 1 0509 NB 1000 Printrd in Japan 1 05 8 23 1 33 PM 1...

Page 99: ...SECTION 4 4 18 1 2 Cylinder T2201 16...

Page 103: ...POWERHEAD 4 23 1 2 Cylinder POWERHEAD Typical 1 Cylinder T1676...

Page 104: ...SECTION 4 4 24 1 2 Cylinder Typical 2 Cylinder T1677...

Page 140: ...SECTION 5 5 22 1 2 Cylinder 8 T1620...

Page 162: ...SECTION 6 6 10 1 2 Cylinder GEARCASE Typical Gearcase 2 5 3 5 T1709...

Page 165: ...GEARCASE 6 13 1 2 Cylinder Typical Gearcase 3 5B T1714...

Page 169: ...GEARCASE 6 17 1 2 Cylinder Typical Gearcase 8 9 8 9 9 15 18 25 30 40 T1723...

Page 214: ...SECTION 7 7 22 1 2 Cylinder Ignition System Performance Testing Flow Chart 1 T1557 1...