96

System Manual V2 – MOVITRAC® B

5

Explanation of the parameters

Parameters

139 / 149

Ramp monitoring 1 / 2

Setting range:

YES

/ NO

If you set the deceleration ramps to a value that is a lot shorter than can be

physically accomplished in this system, the turning drive will be stopped after

expiration of the monitoring time. Such a setting will cause a fault signal and

increase brake wear.

This step also entails an increased setting of the respective ramp, if the ramp

timeout definitely appears in form of a preset ramp that cannot be traveled.

This parameter is an additional monitoring function for speed monitoring. This

parameter only applies to the downwards ramp. This means the parameter can

be used to monitor the downwards ramp, stop ramp or emergency stop ramp if

speed monitoring is not desired.

15_

Motor potentiometer functionn

(se

P100 Setpoint source

)

The ramp times refer to a setpoint change of n = 3000 rpm.

150

Ramp t3 up = down

Setting range 0.2 ...

20

... 50 [s]

The ramp is in effect when using the terminal functions

Motor pot. up

and

Motor

pot. down

.

152

Save last setpoint

off / OFF

The inverter starts with n

min

:

•

After power off and on

•

After revoking ENABLE

If you use the motor potentiometer for permanent speed control, you will

have to set

P152 Save last setpoint to OFF

. Otherwise, error message F25

EEPROM will appear after about 100,000 storage operations.

Store only after setpoint change. If a fixed setpoint is deselected, the fixed

setpoint will be used as motor potentiometer value.

on / ON

The inverter starts with the last set motor potentiometer setpoint:

•

After power off and on

•

After revoking ENABLE

If a fixed setpoint is deselected, the old motor potentiometer setpoint will be

used again.

16_ / 17_

Fixed setpoints 1 / 2

You can activate the fixed setpoints via the binary inputs DI02 ... DI05 with the arguments n11/n21 / n12/n22 and activate FIXED SETP.

CHANGE (parameter 60_). You activate the fixed setpoints n13/n23 by assigning the functions n11/n21 and n12/n22 to two binary

inputs and applying a "1" signal to the two inputs.

160 / 170

Internal setpoint n11 / n21

Setting range –5000 ...

150

... 5000 [rpm]

161 / 171

Internal setpoint n12 / n22

Setting range –5000 ...

750

... 5000 [rpm]

162 / 172

Internal setpoint n13 / n23

Setting range –5000 ...

1500

... 5000 [rpm]

163 / 173

n11/n21 PI controller

Setting range 0 ...

3

... 100 [%] (see section Project planning / PI controller)

164 / 174

n12/n22 PI controller

Setting range 0 ...

15

... 100 [%] (see section Project planning / PI controller)

165 / 175

n13/n23 PI controller

Setting range 0 ...

30

... 100 [%] (see section Project planning / PI controller)

2__

Controller parameters

25_

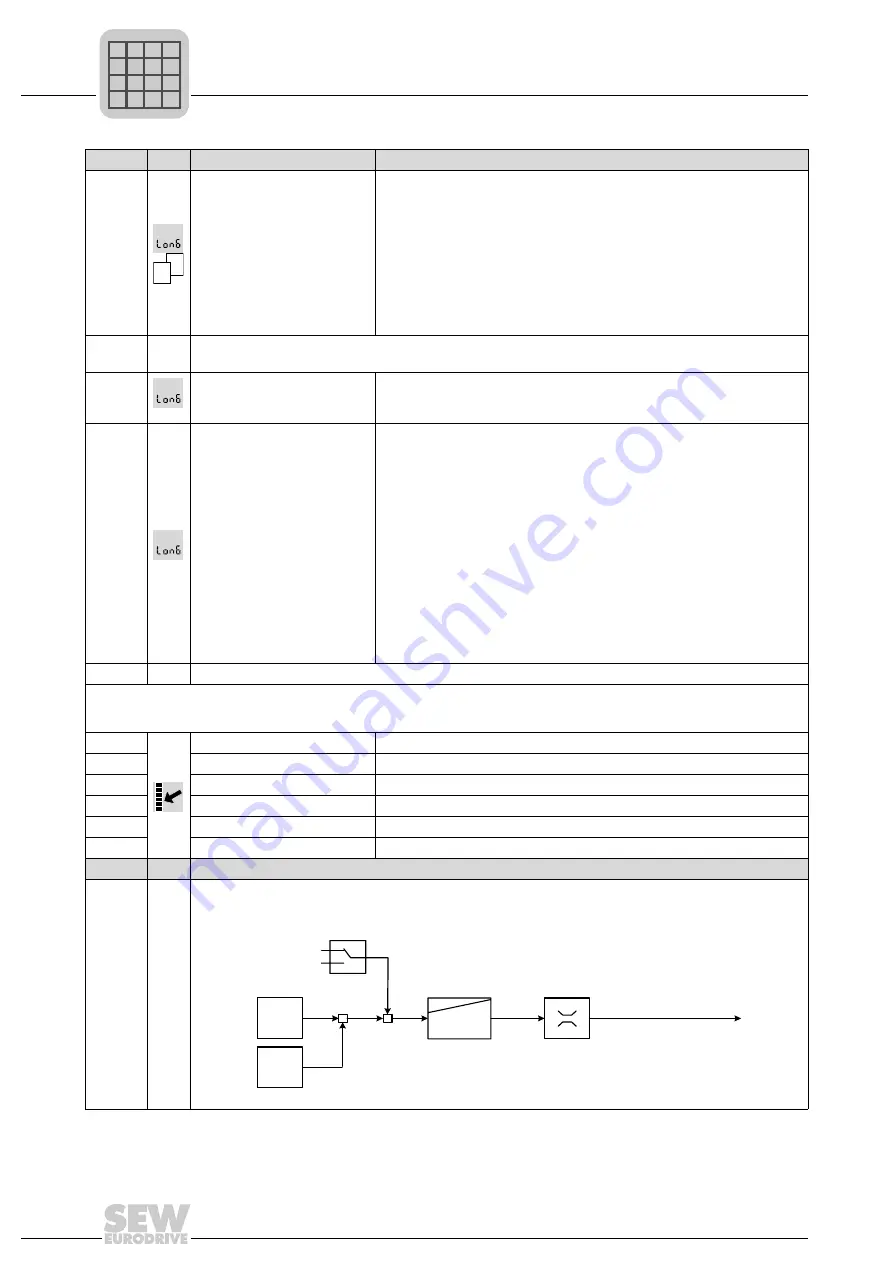

PI controller

(for an explanation of the parameters, refer to the project planning/PI-controller section)

No.

FBG

Name

Description

1

2

Speed setpoint (value)

Actual

value

AI1 %

Setpoint

%

-1

1

n

max

n

min

P251 P-gain

P252 I-component

-

x

P250 PI controller

Normal

Inverted

Contr

ol diff

erence

Correcting

v

ariab

le

P301/311 n

max

P302/312 n

min

P

i

f

kVA

Hz

n

Summary of Contents for MOVITRAC MC07B0037-2A3-4-00

Page 250: ......