2-15

2

Basic oper

a

tion

Media installation and removal

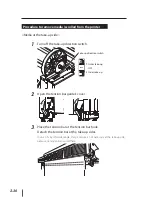

<General media in TENSION winding mode>

Usually put a tension bar suitable for the media width with a few exceptions.

<General media without take-up reel unit>

Put a tension bar which is half the width of the media.

<Vinyl chloride media>

Put an S size tension bar (without a flange) on the center of the slack.

Slacken off to a level lower than the

supply-side slack sensor.

W h e n t h e s l a c k re a c h e s t h e s e n s o r

detection area, the operation panel blips.

Supply-side slack sensor

Peel roller

Scroller

Note

Be sure to rotate the panel with the supply-side feed switch. Do not rotate the

peel roller manually, or the printer may be damaged.

–

19

Check the media setting.

Press the

key.

S E T M E D I A

* O K ?

P R E P A R I N G M E D I A

P L E A S E W A I T

Note

Rewind the printer's media completely at the end of the day. The PVC media

installed and left for a night on the printer may cause media jam.

–