The coolant lubricant prevents the workpiece from overheating. The coolant

lubricant is stored in a tank in the milling unit and before starting wet milling,

ensure that there is enough coolant lubricant in the tank. The fill level must

be between the two markings MIN and MAX.

Steps

1. Put on protective gloves and safety goggles.

2. Open the protective door.

3. If the milling unit has last been used for dry milling, thoroughly clean the

milling unit interior, the filter fleece chips and dry milling dust.

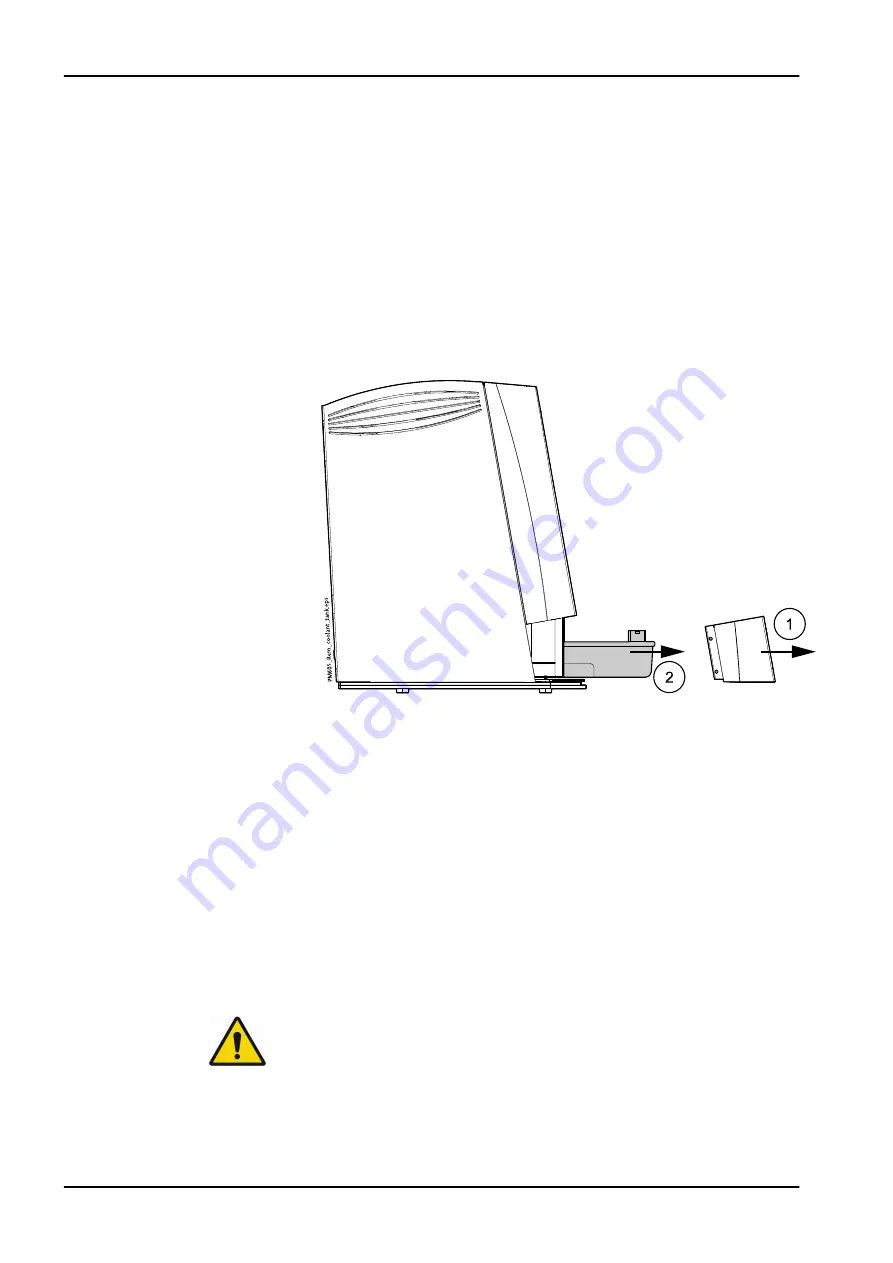

4. Remove the access door (1) to the coolant lubricant tank by pulling it off.

5. Remove the coolant lubricant tank (2).

6. Thoroughly clean all filters and the sump of contaminants.

7. Fill the sump with 3.0 litres of diluted coolant lubricant mixture.

Observe the mixture ratio according to the coolant lubricant system

description.

8. Reinsert the coolant lubricant tank.

9. Close the access door to the coolant lubricant tank.

What to do next

Start the milling process with the coolant lubricant system switched on and

without an extraction system. The milling unit automatically starts cooling

when the milled material requires cooling. See section "Starting milling

16.8.4 Switching between wet and dry milling

WARNING

Thoroughly clean the interior of the milling unit when changing from wet to

dry milling and vice versa, or at least once a day, to prevent the build-up

of material residue and to ensure the proper functioning of the system.

Avoid any mixing of dry dust with the coolant lubricant as the dust / coolant

lubricant mixture can lead to severe contamination of the unit.

16 Operating milling unit

76 Planmeca PlanMill 60 S

User's manual