265

V530-R160

Operation Manual

SECTIO

N

10

Maint

e

na

nce

SECTION 10

SECTIO

N

10

SECTION 10

Appendix

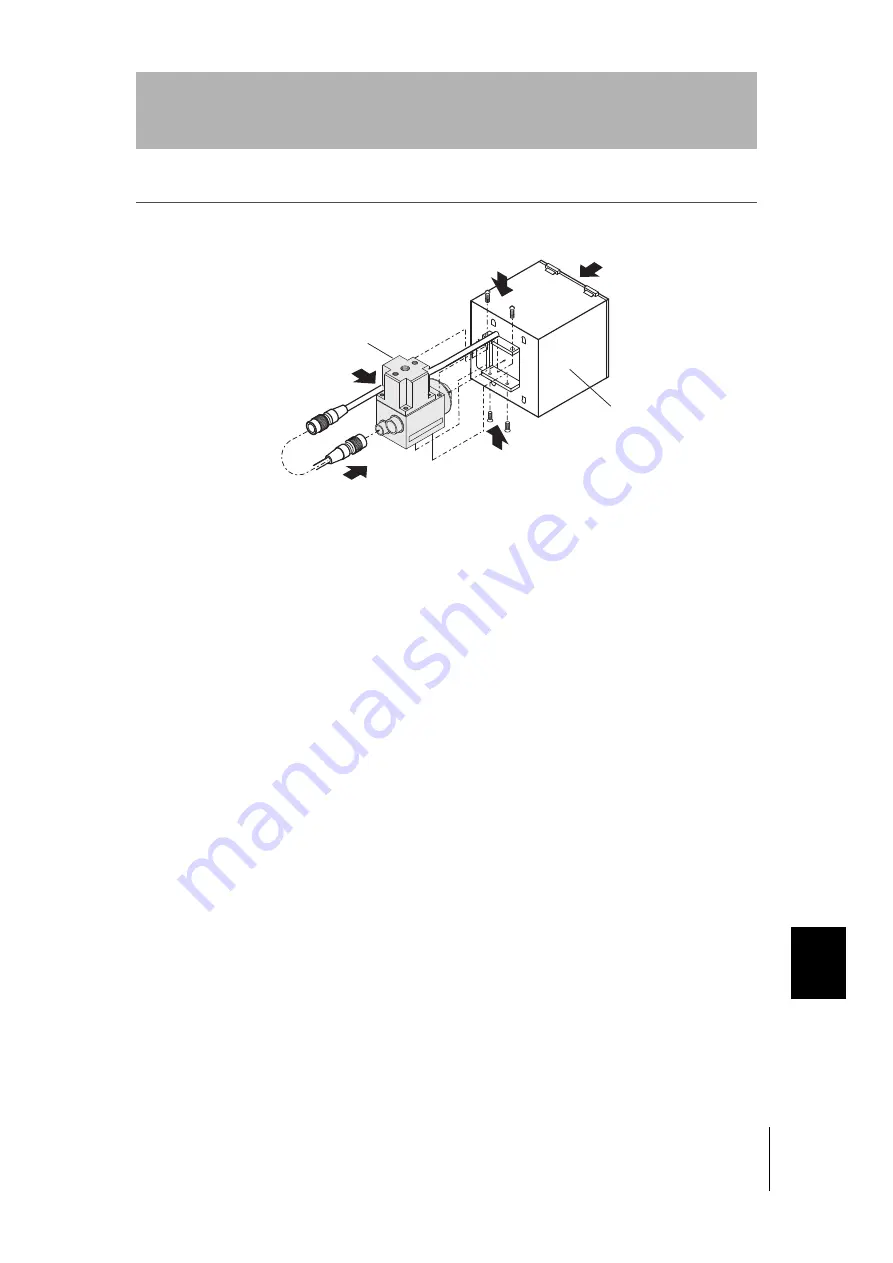

Installing the Light

1.

Fit the light in the Camera.

2.

Replace the bottom two screws that secure the Light.

3.

Replace the two screws that secure the Light.

4.

Insert the light cable in the slot in the camera base.

5.

Connect the light cable to the light connector on the back of the Camera.

5

3

2

1

4

Camera base

Light