Let-

ter

Name

Function

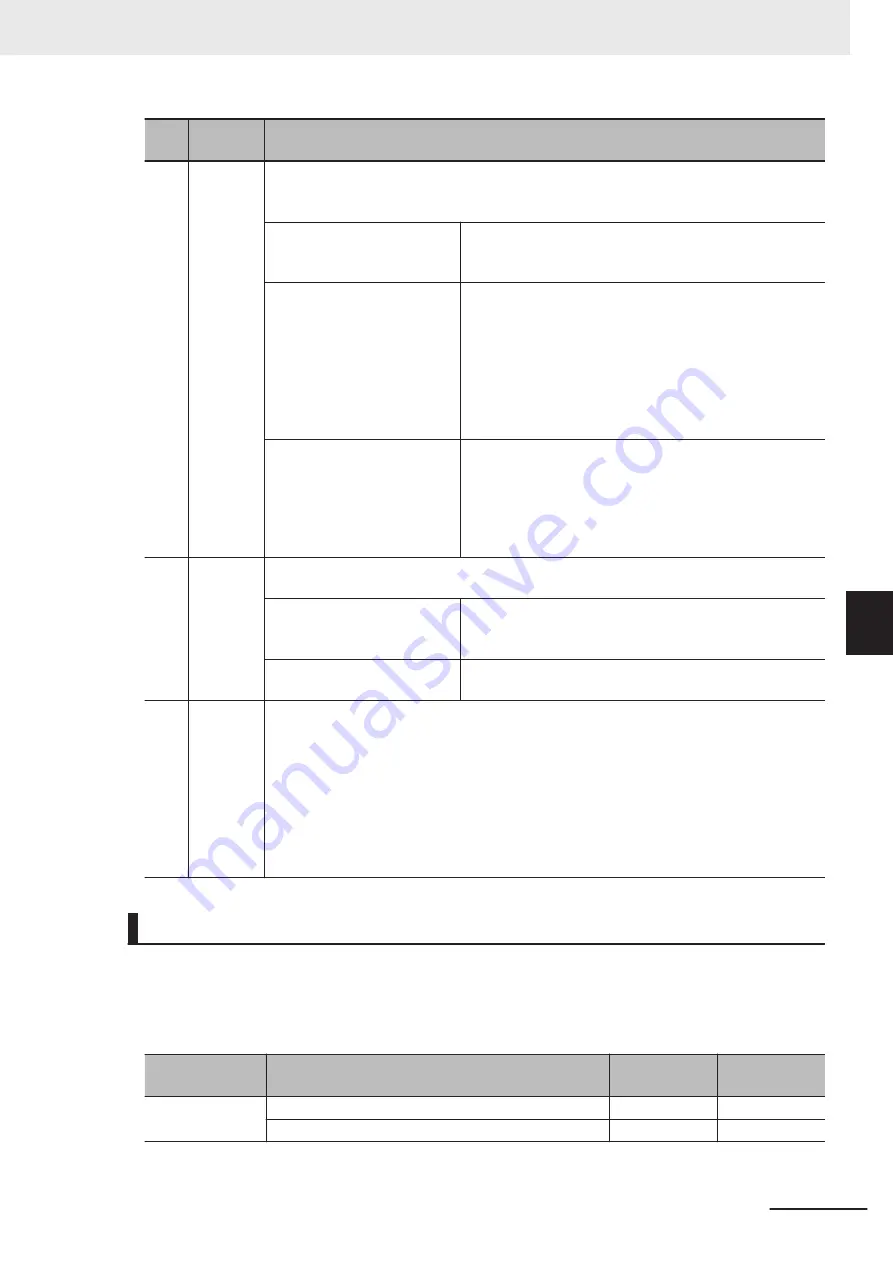

(c)

Input Set-

tings

Specify a variable for the input signal used for automatic programming.

In addition to the variable name, you need to specify a reset type and a linked safety func-

tion block for the input signal.

Variable

Specify a variable name used as input signal for the pro-

gram. You can specify a SAFEBOOL or BOOL-type varia-

ble for the variable name.

Reset Type

Select a reset type in the box. The default value of the re-

set time is a manual reset.

The selected reset type is assigned to the input variable

S_AutoReset

of the safety function block that is linked to

each input signal.

When a program is generated,

S_AutoReset

is set t to

FALSE for a manual reset, and set to TRUE for an auto-

matic reset.

Function Block Name

Specify the name of a safety function block that is linked to

each input signal.

You can also specify a user-defined function block. If you

specify a user-defined function block, you need to define

at least one SAFEBOOL or BOOL-type variable as the in-

put and output variables.

(d)

Output

Settings

Specify a variable for output signal used for automatic programming.

Specify a variable name, and enable or disable EDM for the output signal.

Variable

Specify a variable name used as the output signal for the

program. You can specify a SAFEBOOL or BOOL-type

variable for the variable name.

Use EDM

If it is TRUE, the SF_EDM function block is used when a

program is generated.

(e)

Expected

Value Set-

tings

A matrix of the variables that are specified in the input settings and the output settings is

displayed. Set the expected value of the output variable for each input variable.

The expected values set for the output variables have the following meanings:

•

0

If the input variable changes to FALSE, the output variable changes to FALSE.

•

1

If the input variable changes to FALSE, the output variable changes to TRUE.

You can edit the expected value settings by importing or exporting the values, and copy-

ing and pasting the values with a spreadsheet program or any other application software.

Setting Example

This section provides an example of automatic programming settings for the application example giv-

en in

Application Overview of Safety Laser Scanner

Safety

category/PL

Safety device

Stop category

Reset

Equivalent to

3/PLd

Safety Laser Scanner

0

Auto

Emergency Stop Pushbutton Switch

0

Manual

AGV stops when the emergency stop pushbutton S1 is pressed.

6 Programming

6 - 73

NX-series Safety Control Unit User's Manual (Z930)

6-6 Automatic Programming

6

6-6-2

Automatic Programming Settings

Summary of Contents for NX-SIH400

Page 4: ...Introduction 2 NX series Safety Control Unit User s Manual Z930 ...

Page 46: ...Revision History 44 NX series Safety Control Unit User s Manual Z930 ...

Page 108: ...2 Specifications 2 42 NX series Safety Control Unit User s Manual Z930 ...

Page 132: ...3 Installation and Wiring 3 24 NX series Safety Control Unit User s Manual Z930 ...

Page 148: ...4 Safety Control Unit Operation 4 16 NX series Safety Control Unit User s Manual Z930 ...

Page 216: ...5 System Configuration and Setup 5 44 NX series Safety Control Unit User s Manual Z930 ...

Page 306: ...6 Programming 6 90 NX series Safety Control Unit User s Manual Z930 ...

Page 390: ...8 Calculating Safety Reaction Times 8 12 NX series Safety Control Unit User s Manual Z930 ...

Page 412: ...11 Safety Data Logging 11 10 NX series Safety Control Unit User s Manual Z930 ...

Page 504: ...12 Troubleshooting 12 92 NX series Safety Control Unit User s Manual Z930 ...

Page 554: ...l I O Map Settings Appendices A 42 NX series Safety Control Unit User s Manual Z930 ...

Page 623: ...I Index I 1 NX series Safety Control Unit User s Manual Z930 I ...

Page 625: ......