2. SIGNALS AND WIRING

2 - 3

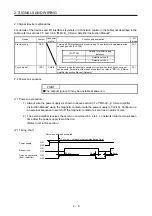

2.1 I/O signal connection example

Servo amplifier

26

(Note 2)

Malfunction (Note 6)

Encoder Z-phase pulse

(open collector)

Encoder A-phase pulse

(differential line driver)

17

DOCOM

15

ALM

11

LA

24

LAR

12

LB

25

LBR

23

LG

SD

10 m or less

Encoder B-phase pulse

(differential line driver)

Control common

CN3

22

INP

In-position

Encoder Z-phase pulse

(differential line driver)

13

LZ

LZR

CN3

5

DICOM

Plate

1

3

2

4

Forced stop2 (Note 3)

Proximity dog

Touch probe 1

Forward rotation

stroke end

Reverse rotation

stroke end

EM2

LSP

LSN

DOG

RA3

(Note 8)

Power supply

24 V DC

(Note 4, 11)

10 m or less

24 V DC (Note 4, 11)

6

(Note 15)

TPR1

18

(Note 15)

OPC

(Note 5)

(Note 9)

16

OP

RA1

RA2

(Note 1)

+

USB cable

(option)

(Note 7)

MR Configurator2

CN5

CN1

CN6

Personal

computer

Ethernet cable

Switching

hub

Modbus RTU

(Note 10, 12, 13)

CC-Link IE Field Network

Basic, SLMP or Modbus/

TCP

(Note 10, 12, 13)

(Note 14)

Note 1. To prevent an electric shock, be sure to connect the protective earth (PE) terminal (marked ) of the servo amplifier to the

protective earth (PE) of the cabinet.

2. Connect the diode in the correct direction. If it is connected reversely, the servo amplifier will malfunction and will not output

signals, disabling EM2 (Forced stop 2) and other protective circuits.

3. The forced stop switch (normally closed contact) must be installed.

4. Supply 24 V DC ± 10% to interfaces from outside. The total current capacity of these power supplies must be 300 mA or lower.

300 mA is the value applicable when all I/O signals are used. The current capacity can be decreased by reducing the number

of I/O points. Refer to section 3.9.2 (1) of "MR-JE-_C Servo Amplifier Instruction Manual" that gives the current value

necessary for the interface. The illustration of the 24 V DC power supply is divided between input signal and output signal for

convenience. However, they can be configured by one.

5. When starting operation, always turn on EM2 (Forced stop 2), LSP (Forward rotation stroke end) and LSN (Reverse rotation

stroke end) (normally closed contact).

6. ALM (Malfunction) turns on in normal alarm-free condition (normally closed contact). When this signal is switched off (at

occurrence of an alarm), the output of the programmable controller should be stopped by the sequence program.

7. Use SW1DNC-MRC2-_. MR-JE-_C Servo Amplifier Instruction Manual section 11.4

8. Configure a circuit to turn off EM2 when the power is turned off to prevent an unexpected restart of the servo amplifier.

9. You can change devices of these pins with [Pr. PD30], [Pr. PD31], [Pr. PD32], and [Pr. PD38].

10. For communication function, refer to the "MR-JE-_C Servo Amplifier Instruction Manual (Network)”.

11. This diagram shows sink I/O interface.

12. Modbus/TCP can be used on servo amplifiers with software version A3 or later. Modbus RTU can be used on servo amplifiers

with software version A4 or later.

13. Ethernet communication (CC-Link IE field network Basic, SLMP and Modbus/TCP) and RS-485 communication (Modbus RTU)

are exclusively independent functions. Only the communication function selected in [Pr. PN08] "Select communication

function" can be used.

14. If this servo amplifier is the last axis, connect a 150 Ω resistor between DA and DB, and terminate the servo amplifier. For

details, refer to the "MR-JE-_C Servo Amplifier Instruction Manual (Network)”.

15. When CN3-6 pin is used as the input device of sink interface, of 24 V DC to CN3-18 pin (OPC: power input for open-

collector sink interface).

Summary of Contents for MELSERVO-JE

Page 15: ...1 FUNCTIONS AND CONFIGURATION 1 4 MEMO ...

Page 21: ...2 SIGNALS AND WIRING 2 6 MEMO ...

Page 57: ...4 PARAMETERS 4 34 MEMO ...

Page 109: ...6 SERVO MOTOR DRIVING 6 44 MEMO ...

Page 111: ...7 APPLICATION OF FUNCTIONS 7 2 MEMO ...

Page 113: ...MEMO ...