Replacing consumables

4-42

10

Check the state of the waste ink tank

• Test drawing starts.

11

Press the

key several times to end the setting.

12

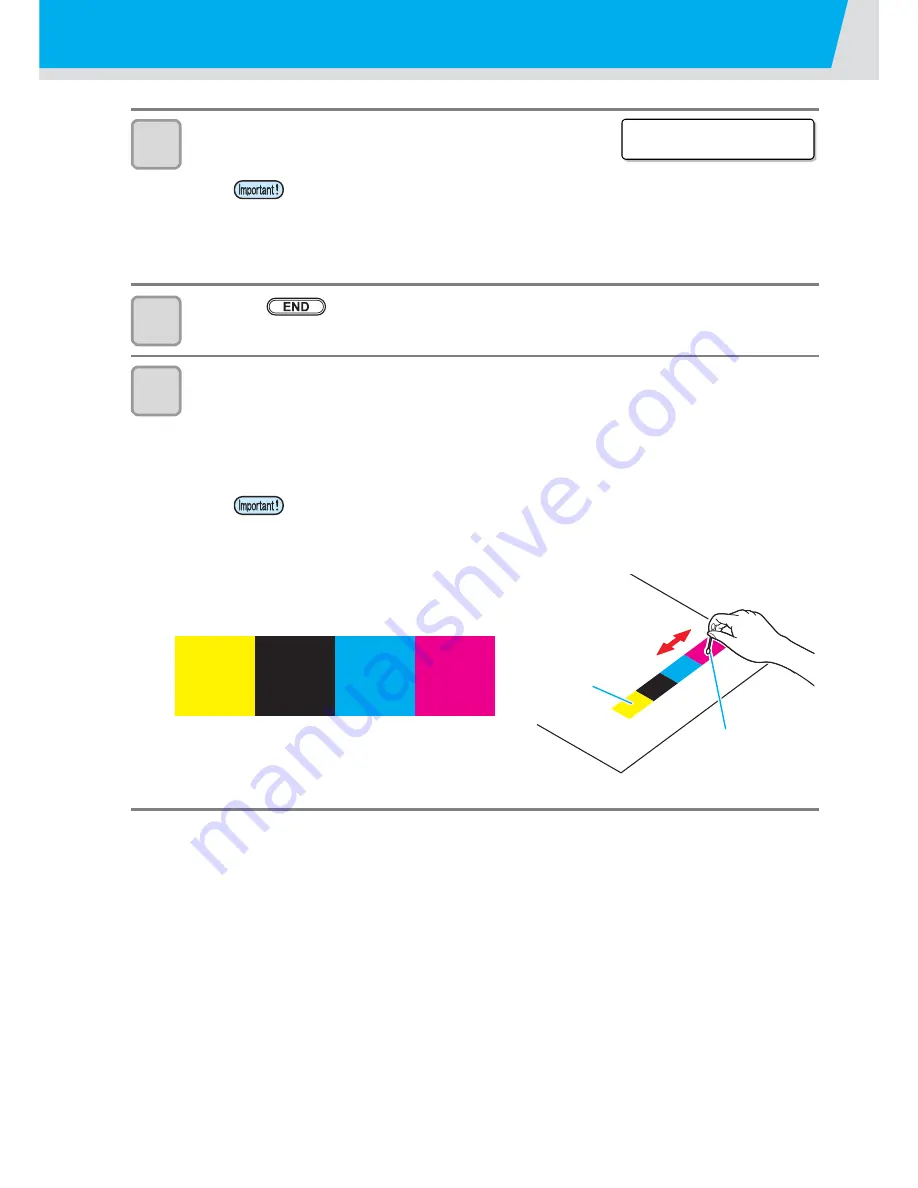

Check the drawing pattern after the test drawing.

• Rub print surface with the cotton swab saturated with cleaning liquid 10 strokes.

• Check the change of the surface by visual inspection.

When the print surface is peeled off, UV light intensity is weakened.

When any change is not found, there is no problem on UV lights.

• If the UV light intensity is weak, the rub fastness is significantly reduced.

• If the temperature of the UV lamp has not reached the predetermined value,

a message appears. In this case, it is not drawn. When the display

disappears, drawing can be started.

• If you open the shading cover while the UV lamp lights, the UV lamp is turned off.

However, the operation will continue.

• When UV light intensity is weakened, UV lamps are weakened. If the U

V ink curing

level is not improved after adjusting the UV light intensity, the UV LED is

deteriorated. Contact your local distributor or call for service.

* * PR I NT I NG * *

P L EASE WA I T

Cotton swab saturated

with cleaning liquid

Print surface

10 strokes

Summary of Contents for JV400-130SUV

Page 1: ...MIMAKI ENGINEERING CO LTD URL http eng mimaki co jp D202394 17 Original instructions ...

Page 58: ...2 28 ...

Page 73: ...3 15 1 1 3 Convenient use 5 6 9 Press the key several times to end the setting ...

Page 100: ...3 42 ...

Page 162: ...5 20 ...

Page 179: ...Function Flowchart 6 17 Appendix 6 ...

Page 187: ...Function Flowchart 6 25 Appendix 6 ...

Page 192: ...6 30 ...