3-84

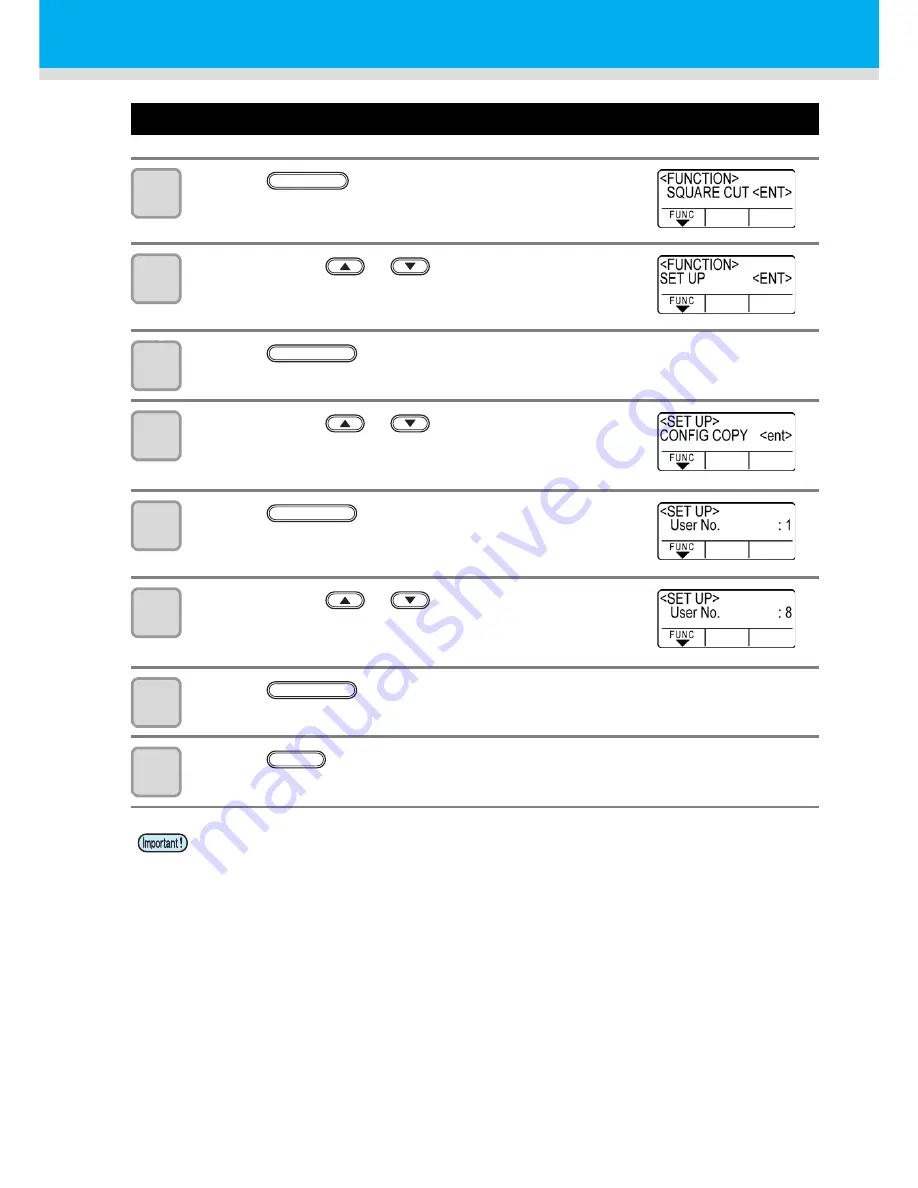

Copy the set value from the other user setting.

1

Press the

key in the local mode.

2

Press the jog key

or

to select [SET UP] .

3

Press the

key.

4

Press the jog key

or

to select [CONFIG

COPY].

5

Press the

key.

6

Press the jog key

or

to select the user

setting number to copy.

7

Press the

key.

• Copy the setting item of the user selected in the Step 6 to the current user.

8

Press the

key two times for terminating this reset operation.

• The setting values are kept in memory even when the power is turned off.

FUNCTION

ENTER/HOLD

ENTER/HOLD

ENTER/HOLD

END

Summary of Contents for CG-100SRIII

Page 24: ...1 12...

Page 136: ...3 86...

Page 161: ...5 17 Function Flowchart 1 1 1 1 5 Appendix ENTER HOLD 10 30cm 10 50cm...

Page 169: ...Function Flowchart 5 25 1 1 1 1 5 Appendix ENTER HOLD FUNCTION ENTER HOLD FUNCTION...

Page 170: ...5 26...

Page 171: ...D202472 16 19052014...