262391

150

Revision A

WARNING

Exercise caution when working around the blades. Blades are sharp and can cause serious injury. Wear gloves when

handling blades.

1.

Position the rotary disc header at an appropriate height for the task.

2.

Shut down the engine, and remove the key from the ignition.

3.

If the rotary disc header is raised:

a.

Place blocks under each end, or just inside each end, of the cutterbar.

b.

Lower the rotary disc header onto the blocks.

c.

Shut down the engine, and remove the key from the ignition.

d.

Close the auxiliary lift cylinder lock-out valves. For instructions, refer to

3.2.1 Locking and Unlocking Auxiliary Lift

.

1017492

A

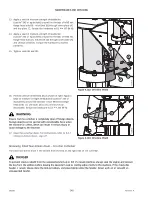

Figure 4.125: Non-Driven Spindle

4.

Ensure spacer (A) is on the spindle.

1024913

A

A

A

A

B

Figure 4.126: Non-Driven Drum

5.

Position non-driven disc assembly (B) onto the spindle

as shown.

6.

Install four M12 bolts (A) and the washers securing the disc

assembly to the spindle. Torque the hardware to 55 Nm

(40 lbf·ft).

WARNING

Ensure that the cutterbar is completely clear of foreign objects.

Foreign objects can be ejected with considerable force when

the machine is started, which can result in serious injury or

cause damage to the machine.

7.

Close the cutterbar doors. For instructions, refer to