215922

263

Revision A

5.6.2

Tightening Caster Wheel Nuts

At first use or when a wheel is removed, check wheel nut/bolt torque every 15 minutes on the road or 1 hour in the field

until the specified torque is maintained. Once specified torque is maintained, check wheel nut/bolt torque after 10 and 50

hours (field or road operation), and then every 200 hour intervals thereafter.

1023262

A

Figure 5.35: Caster Wheel Location

1.

Locate caster wheel assemblies (A).

1000549

A

1

2

3

4

5

6

7

8

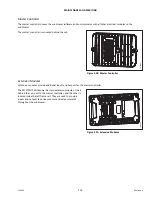

Figure 5.36: Forked Casters with Suspension

2.

Tighten wheel nuts (A) to 163 Nm (120 lbf·ft) using the

tightening sequence shown at right. Repeat the tightening

sequence three times.

5.6.3

Tightening Caster Wheel Anti-Shimmy Dampeners

1034206

A

B

C

D

Figure 5.37: Anti-Shimmy Dampener

Each caster is equipped with two fluid-filled anti-shimmy

dampeners (A).

Mounting bolts (B) and (C) need to be checked periodically for

security. For inspection intervals, refer to

•

Two inboard bolts (B) should be tightened to 136 Nm

(100 lbf·ft)

•

Outboard bolt (C) should be tightened to 244 Nm (182 lbf·ft)

•

Outboard jam nut (D) should be tightened to 136 Nm

(100 lbf·ft)