Victorum Exhaust Air Heat Pump Installation Guide

37

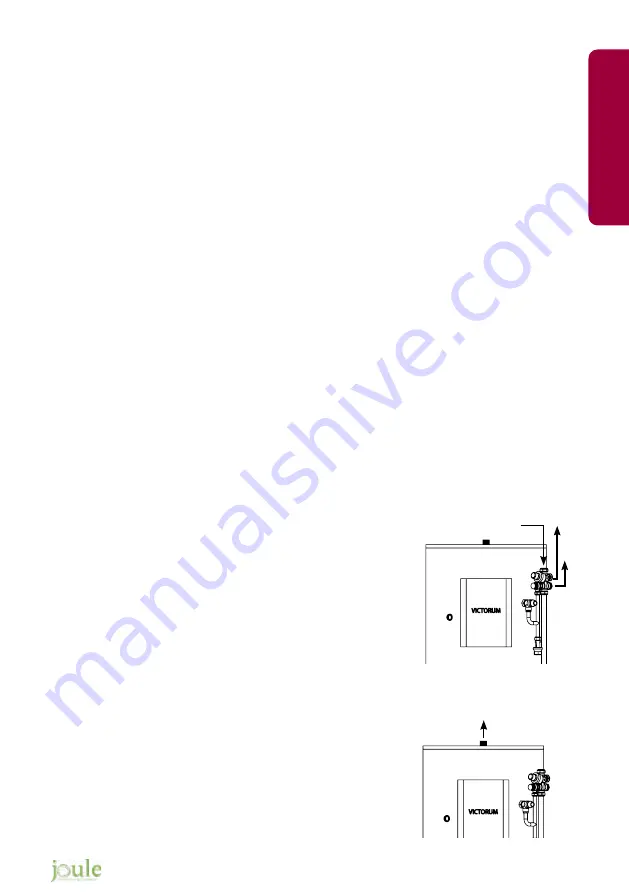

Victorum PrePlumb

Piping

Connecting to the Inlet Control Group

Excess pressure can lead to the cylinder bursting. The inlet control set supplied has an expansion

relief valve with a 15mm connection to allow it to be connected to a tundish, this is pre-plumbed. Make

sure that there is enough space for future maintenance and for connection of the discharge pipe for

the expansion relief valve. It is essential that this connection is not covered or closed.

The cold inlet must be piped into the top of the inlet control group. It is recommended to install a full

bore isolation valve on the cold inlet for maintenance and servicing of the valve.

Water Supply

The performance of any unvented system is only as good as the mains water supply available. To this

effect the maximum possible water demand should be assessed, with the knowledge that the mains

supplies both hot and cold services simultaneously. The hot water storage tank/ water heater itself

operates at a pressure of 3bar, controlled by the inlet control set, and is capable of delivering over

50 litres per minute. The high quality inlet control set has been designed to make the most of the low

rates available.

The water supply should be checked to ensure it can meet these requirements. If necessary, consult

the local water authority regarding the likely pressure and flow rate availability. Consideration should

be given to upgrading existing 1⁄2” (15mm) cold mains pipework to a larger size if the recommended

minimum pressure / flow rateis not being achieved. Joule™ recommend that primary pipework used

has a minimum diameter of 22mm to ensure low pressure loss.

Potable Expansion Vessel

The expansion vessel receives the increased water volume when

expansion takes place as the system heats up and it maintains a

positive pressure in the system. The expansion vessel contains

a flexible diaphragm, which is initially charged on one side with

nitrogen, but can be topped up with air when required. Select

a suitable position for the expansion vessel. Mount it to the wall

using the bracket provided (0-24L only, 35L and above are floor

standing) and hard fix into pipework and insulate. Ensure that the

top of the vessel is accessible for servicing. The pipe connecting

the expansion vessel to the system should have a diameter of not

less than 15mm and must not contain any restrictions.

Hot Water Outlet

Run the first part of the hot water distribution pipework in 22mm.

This can be reduced to 15mm and 10mm as appropriate for the

type of tap etc. Your aim should be to reduce the volume of the hot

draw-off pipework to a practical minimum so that the time taken

for the hot water is as quick as possible. Do not use monobloc

mixer tap or showers if the balanced cold connection is not pro-

vided. Outlets of this type can back pressurise the unit and result

in discharge.

Potable

Vessel

Mains/Boosted

Supply Inlet

Balanced

Cold Outlet