2-14

Data subject to change without notice 7/07. © 2007 GE Drives

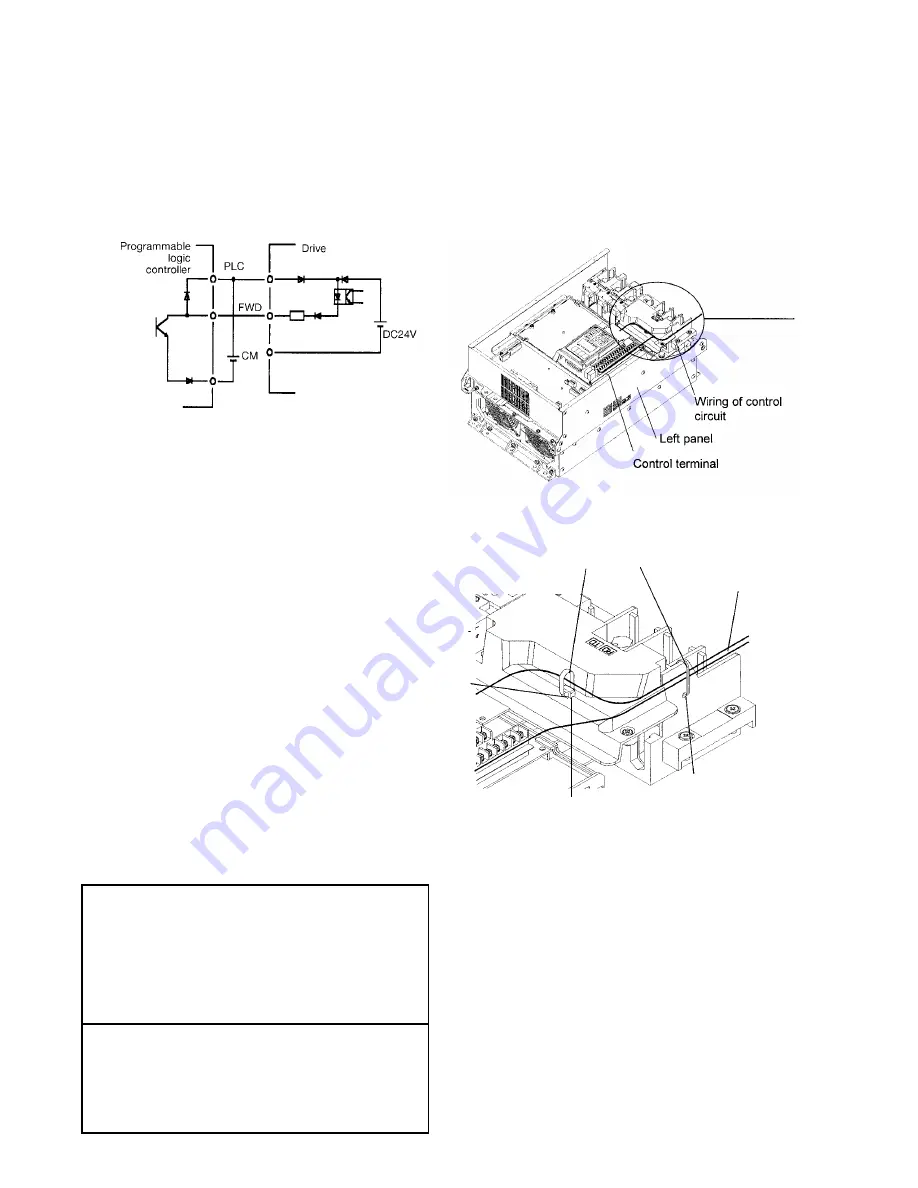

(2) Digital input terminals (FWD, REV, X1 to X9, PLC,

and CM)

1.

Digital input terminals (e.g., FWD, REV, X1 to X9) are

generally turned on or off by connecting or discon-

necting the line to or from the CM terminal.

If digital input terminals are turned on or off by

switching the PLC’s open collector output using an

external power supply, a resulting bypass circuit may

cause the drive to malfunction. To prevent a malfunc-

tion, connect the PLC terminal as shown in Fig. 2-3-

11.

Fig. 2-3-12 The Control Wiring Route

Fig. 2-3-13 Securing Positions for Inverter Control Circuit Wiring (40 HP or more)

Fig. 2-3-11 Prevention of Bypass Current by External Power

2.

When using a contact input, a high-quality relay with

reliable contacts must be used.

(3) Transistor output terminals (Y1 to Y4, CMY)

1.

These terminals have a circuit configuration as shown

in Table 2-3-3, "Transistor Output". Confirm the

polarity of the external power supply.

2.

To connect a control relay, connect a surge absorbing

diode to both ends of its exciting coil.

(4) Sink or Source Logic Selection.

1.

Set SWI for Sink or Source Connection to the PLC.

The factory default setting is Sink and this instruction

manual explains Sink logic function only.

2.

When you need to connect source type logic, refer to

Basic Connection Diagram Fig. 2-3-3 and Fig. 2-3-4

and Technical Information Manual. (Sink Logic is

commonly used in the USA and Source Logic is

commonly used in Europe.)

(5) Others

1.

To prevent a malfunction as a result of noise, control

terminal cables must be placed as far as possible

from the main circuit cables.

2.

The control cables inside the inverter must be

secured to prevent direct contact with the main circuit

(e.g., main circuit terminal block).

wiring

Cable ties

Cable

binding

Hole A

Cable binding

Hole B

(6) Wiring of control circuit (inverter of 40 Hp or more)

1.

Pull out the control circuit wiring along the left panel

as shown in Fig. 2-3-12.

2.

Secure the cable to cable binding hole A (on the left

wall of the main circuit terminal block) using a cable-

tie

(e.g., Insulock). The cable-tie must not exceed 0.14"

(3.5mm) in width and 0.06" (1.5mm) in thickness.

3.

When the optional PC board is mounted, the signal

lines must be secured to cable binding hole B.

WARNING

Control lines generally do not have enhanced

insulation. If the insulation of a control line is

damaged, the control signals may be exposed to

high voltage in the main circuit. The Low Voltage

Directive in Europe also restricts the exposure to

high voltage. Electric shock may result

CAUTION

The inverter, motor, and cables generate noise.

Check that the ambient sensors and devices do

not malfunction. Accident may result.

Summary of Contents for AF-300 P11

Page 1: ...GE Consumer Industrial AF 300 P11 User s Guide ...

Page 35: ...2 18 Data subject to change without notice 7 07 2007 GE Drives Notes ...

Page 37: ...3 2 Data subject to change without notice 7 07 2007 GE Drives Notes ...

Page 53: ...4 16 Data subject to change without notice 7 07 2007 GE Drives Notes ...

Page 62: ...5 9 Frequency Setting Block Diagram ...

Page 66: ...5 13 ...

Page 84: ...5 31 Notes ...

Page 99: ...5 46 Notes ...

Page 109: ...7 8 Data subject to change without notice 7 07 2007 GE Drives Notes ...

Page 115: ...8 6 Data subject to change without notice 7 07 2007 GE Drives Notes ...

Page 123: ...10 6 Data subject to change without notice 7 07 2007 GE Drives Notes ...