Chapter 4

1. Inverter and Motor Selection

4-6

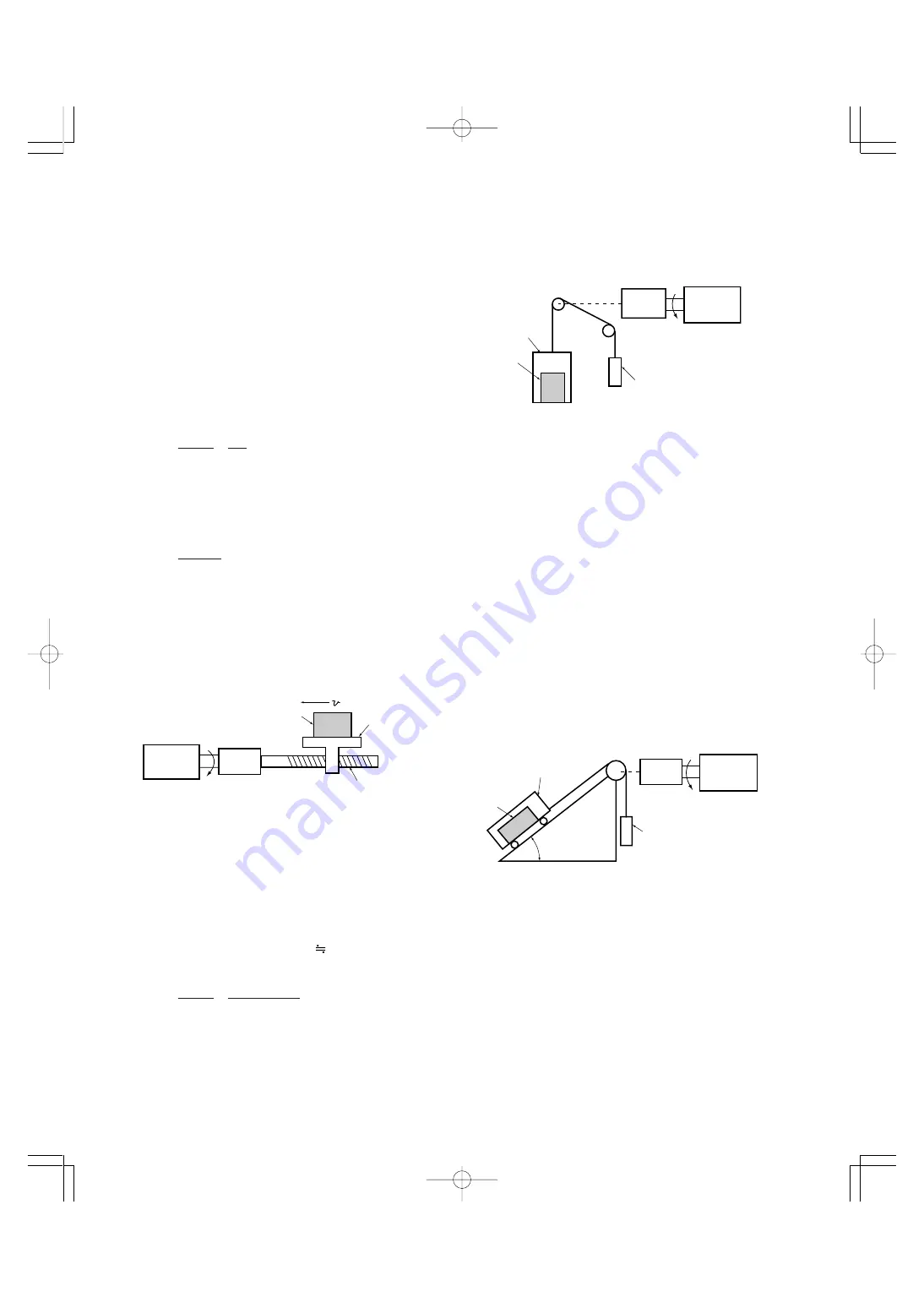

(2) Moving a load vertically

As shown in Fig. 4.8, where a cage weight, load weight,

and balance-mass weight are W

0

, W, and W

B

[kg], the

force of gravity F [N] is as follows:

(Lifting)

F = (W

0

+ W – W

B

) · g

[N] ...................................... (4.5)

(Lowering)

F = (W

B

+ W – W

0

) · g

[N] ...................................... (4.6)

Where maximum load is W

max

, generally W

B

equals to

(W

o

+ W

max

) / 2. So, F may become a negative force to

brake both lifting and lowering movements depending on

the load weight.

Calculate the required torque

τ

around the motor shaft in

the driving mode by expression (4.1) and that in the

braking mode by expression (4.2). That is, if F is positive,

use expression (4.1); if it is negative, use expression

(4.2).

(3) Moving a load along a slope

Lifting and lowering a load along a slope may seem to be

like lifting and lowering a load vertically, but friction force

between the load and the slope cannot be ignored in

lifting and lowering along a slope. Therefore, the expres-

sion for lifting a load is a little different from that for

lowering a load. Where slope angle is

θ

and friction

coefficient is

µ

, as shown in Fig. 4.9, driving force F [N] is

as follows:

(Lifting)

F= ((W

0

+ W)(sin

θ

+

µ

· cos

θ

) – W

B

) · g

[N] ............... (4.7)

(Lowering)

F=(W

B

– (W

0

+ W)(sin

θ

–

µ

· cos

θ

)) · g

[N] ............... (4.8)

Balance weight

Cargo

Load

Reduction-gear

Motor

W

B

[kg]

N

M

[r/min]

W [kg]

W

0

[kg]

Balance weight

Load

Carrier

Reduction-gear

Motor

W [kg]

W

o

[kg]

W

B

[kg]

N

M

[r /min]

θ

1.3 Selection calculation expressions

1.3.1 Load torque during constant speed running

1. General expression

The frictional force acting on a horizontally moved load

must be calculated. For loads lifted or lowered vertically or

along a slope, the gravity acting on the load must be

calculated. Calculation for driving a load along a straight

line with the motor is shown below.

Where the force to move a load linearly at constant speed

υ

[m/s] is F[N] and the motor speed for driving this is

N

M

[r/min], the required motor output torque

τ

M

[N·m] is as

follows:

τ

M

= 60

υ

·

F

2

π

· N

M

η

G

[N·m] ............................................ (4.1)

Where,

η

G

: Reduction-gear efficiency

When the motor is in braking mode, efficiency works

inversely, so the required motor torque should be calcu-

lated as follows:

τ

M

=

60

υ

·F ·

η

G

2

π

· N

M

[N·m] ........................................ (4.2)

(60

υ

)/(2

π

·N

M

) in the above expression is an equivalent

rotation radius corresponding to speed

υ

around the motor

shaft.

The value F in the above expressions changes according

to the load type.

2. Obtaining the required force F

(1) Moving a load horizontally

As shown in Fig. 4.7, where the carrier table weight is W

0

[kg], load is W [kg], and friction coefficient of the ball

screw is

µ

, friction force F [N] is expressed as follows:

F = (W

0

+ W) · g ·

µ

[N] ...................................... (4.3)

Where, g : Gravity acceleration ( 9.8 m/s

2

)

Then, required driving torque around the motor shaft is

expressed as follows:

τ

M

= 60

υ

·

(W

0

+W) · g ·

µ

2

π

·N

M

η

G

[N·m] ......................... (4.4)

Load

Reduction-gear

Motor

Ball screw

Carrier table

N

M

[r/min]

W

0

[kg]

W [kg]

[m/s]

Fig. 4.7 Moving a load horizontally

Fig. 4.8 Moving a load vertically

Fig. 4.9 Moving a load along a slope

Summary of Contents for FRENIC5000G11S Series

Page 1: ......

Page 2: ......

Page 154: ...3 30 3 12 13 P23 30 65p 07 8 9 12 34 Page 30 Adobe PageMaker 6 5J PPC...

Page 166: ...4 12...

Page 182: ...3 12 13 P23 30 65p 07 8 9 12 34 Page 30 Adobe PageMaker 6 5J PPC 5 16...

Page 212: ...3 12 13 P23 30 65p 07 8 9 12 34 Page 30 Adobe PageMaker 6 5J PPC 6 30...

Page 234: ...MEMO Chapter8 4 P15 p65 07 8 9 12 57 Page 18 Adobe PageMaker 6 5J PPC...

Page 235: ......

Page 236: ......