161

E13

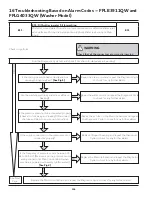

E13: Water leakage

E13

Wrong drain pipe position (siphon), Water leak, Water flow too low, Water inlet

valve, Pressure sensor or hose.

Checks to perform:

WARNING

Check that all the connectors are correctly inserted

Are the washing machine’s water lines efficient (leaking)?

Repair the water circuit and repeat the Diagnostic Cycle

to check for any further alarms.

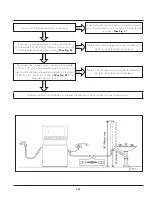

Is the drain pipe positioned correctly and not causing the

siphon effect?

(See Fig.1)

Repair the drain circuit and repeat the Diagnostic Cycle

to check for any further alarms.

Is the water supply proper? [Water pressure must be

between10 psi (0.69 bars) and 120 psi (8.27 bars), Pressure

difference between hot and cold cannot be more than

10psi.]

Make water supply proper and repeat the Diagnostic

Cycle to check for any further alarms.

Is the air tube connected properly (check also for kinking

and leaking)? (Disconnect the tubes and blow into them to

make sure the system is unobstructed)

(See Fig. 2)

Replace / Repair the air tube and repeat the Diagnostic

Cycle to check for any further alarms.

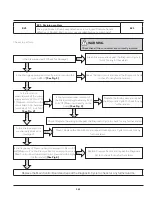

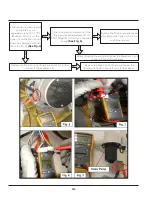

Is the frequency of Pressure Sensor between 45 Hz to 45.5

Hz? (Measure it on the pressure sensor wiring connector at

Main Control Board when machine is powered with empty

tub (No water))

(See Fig.3)

Replace Pressure sensor and repeat the Diagnostic

Cycle to check for any further alarms.

Is the resistance measurement of the Solenoid valve

approximately 1375Ω ± 10%? (Measure it directly on the

Solenoid Valve terminal without wiring

(See Fig. 4)

See Next Page

Replace the Solenoid Valve and repeat the Dagnostic

Cycle to check for any further alarms.

N

O

Y

E

S

Y

E

S

Y

E

S

Y

E

S

Y

E

S

NO

NO

NO

NO

NO

YES

Summary of Contents for FFLE3911QW

Page 1: ...Publication 5995666392 October 2015 Technical Service Manual Laundry Center ...

Page 2: ...I ...

Page 9: ...8 3 Product Features ...

Page 14: ...13 5 1 FFLE3911QW 5 1 1 Upper Cabinet Drum Heater 5 Exploded View and List of Parts ...

Page 17: ...16 5 1 2 Motor Blower Belt ...

Page 19: ...18 5 1 3 Control Panel ...

Page 21: ...20 5 2 FFLG4033QW 5 2 1 Upper Cabinet Drum Heater ...

Page 24: ...23 5 2 2 Motor Blower Belt ...

Page 27: ...26 5 2 3 Control Panel ...

Page 32: ...31 5 3 3 Wash Assembly POS NO DESCRIPTION 14 Screw 2 PLCS 15 Lock Hub Functional parts ...

Page 33: ...32 5 3 4 Cabinet Assembly ...

Page 69: ...68 User Interface of Laundry Center FFLG4033QW ...

Page 76: ...75 8 6 Wiring Diagram FFLE3911QW Electric Dryer Model ...

Page 77: ...76 8 7 Wiring Diagram FFLG4033QW Gas Dryer Model ...

Page 78: ...77 8 8 Wiring Diagram FFLE3911QW and FFLG4033QW Washer Model ...

Page 91: ...90 Wiring Diagram FFLE3911QW Wiring Diagram FFLG4033QW ...

Page 125: ...124 ...

Page 161: ...160 ...

Page 165: ...164 ...

Page 168: ...167 ...

Page 170: ...169 ...

Page 179: ...178 ...

Page 181: ...180 ...

Page 183: ...182 ...