149

This information is intended for qualified technicians only.

CAUTION

DISCONNECT ELECTRICAL CURRENT BEFORE

SERVICING

Acronyms:

CW

- Clockwise

CCW

- Counter Clockwise

Cold Power On

- Unit plugged in for the first time

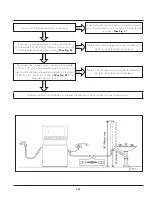

15.1 Reading Error Codes

Enter the Diagnostic Mode to read error codes (Refer to the

instructions below on how to enter this mode):

• The last recorded error code will be displayed first.

• Start/Pause/Cancel buttons should be pressed

momentarily (any time less than 1sec) to cycle through

the last 5 error codes recorded.

• E00 signifies no error code and is accompanied by no

buzzer beeps.

• Press and hold the Start/Pause/Cancel button for a

duration >= 4 seconds to clear all error codes.

Error Code Display Method -

Buzzer equipped

1. The buzzer beeps the same number of times as the first

digit of the error code (0.5 sec ON/ 0.5 sec OFF).

For example:

If the first digit is 3, the buzzer sequence will be 0.5 seconds

ON/0.5 seconds OFF/0.5 seconds ON/0.5 seconds OFF/0.5

seconds ON/0.5 seconds OFF. A, B, C, D, E, F corresponds

to the buzzer digit readings of 10, 11, 12, 13, 14, and 15,

respectively.

2. The buzzer stays silent for 2 seconds.

3. The buzzer beeps the same number of times as the

second digit of the error code (0.5 seconds ON/0.5 seconds

OFF).

4. The buzzer stays silent until the Start/Pause/Cancel

buttons are pressed momentarily to read the next error

code.

15.2 Diagnostic Mode

Use this mode under the following conditions:

• In a factory assembly line to perform a manual test of

the machine functionality (final assembly test)

• By service personell to check for faults and repair the

machine

• In the labs to check the machine functions

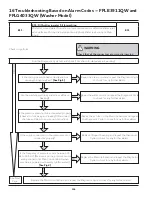

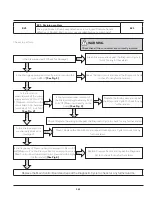

15.3 Entering the Diagnostic

Mode

Follow the instructions given below to enter the Diagnostic

Mode:

1. Plug the unit in or do a full control reset, which is

described in other documents. Set the Cycle Selector knob

at the 9 o’clock (presoak) position and the temperature

knob at the far left CCW position hot for LC1 (Model –

FFLE3911QW) & LC2 (Model – FFLG4033QW) and press

the Selector knob momentarily (<1 second). The other

knobs and switches do not matter.

2. Within 5 seconds, move the temperature knob to

the far right position CW and push the Selector knob

momentarily (<1 second). Move the temperature selector to

the far left CCWand push the Selector knob momentarily

(<1 second). There will be a long beep signalling the entry

into the Diagnostic/Line Test Mode. If not, start over with an

effort to perform the series of events faster or with more

precision.

15. Diagnostic System - FFLE3911QW and FFLG4033QW

(Washer)

Summary of Contents for FFLE3911QW

Page 1: ...Publication 5995666392 October 2015 Technical Service Manual Laundry Center ...

Page 2: ...I ...

Page 9: ...8 3 Product Features ...

Page 14: ...13 5 1 FFLE3911QW 5 1 1 Upper Cabinet Drum Heater 5 Exploded View and List of Parts ...

Page 17: ...16 5 1 2 Motor Blower Belt ...

Page 19: ...18 5 1 3 Control Panel ...

Page 21: ...20 5 2 FFLG4033QW 5 2 1 Upper Cabinet Drum Heater ...

Page 24: ...23 5 2 2 Motor Blower Belt ...

Page 27: ...26 5 2 3 Control Panel ...

Page 32: ...31 5 3 3 Wash Assembly POS NO DESCRIPTION 14 Screw 2 PLCS 15 Lock Hub Functional parts ...

Page 33: ...32 5 3 4 Cabinet Assembly ...

Page 69: ...68 User Interface of Laundry Center FFLG4033QW ...

Page 76: ...75 8 6 Wiring Diagram FFLE3911QW Electric Dryer Model ...

Page 77: ...76 8 7 Wiring Diagram FFLG4033QW Gas Dryer Model ...

Page 78: ...77 8 8 Wiring Diagram FFLE3911QW and FFLG4033QW Washer Model ...

Page 91: ...90 Wiring Diagram FFLE3911QW Wiring Diagram FFLG4033QW ...

Page 125: ...124 ...

Page 161: ...160 ...

Page 165: ...164 ...

Page 168: ...167 ...

Page 170: ...169 ...

Page 179: ...178 ...

Page 181: ...180 ...

Page 183: ...182 ...