152

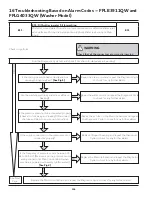

15.10 Three Water Valves Test

Selector position

Turn 4 clicks clockwise from the top

Purpose of the test

To test both hot and cold and, if present, the softener water valves and the softener

siphon drains fully, agitate function

Activated components

Door lock, three water valves, main motor

UI behaviour

None

Working conditions

Door locked, Add while water level lower than 55mm, for max. 5 minutes. The clutch

moves to the agitate position, if it was in spin. Agitate begins when the water level is

reached

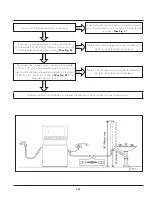

15.11 Drain and Clutch Test

Selector position

Turn 5 clicks clockwise from the top

Purpose of the test

Drain system with the clutch mechanism

Activated components

Door lock, drain pump, clutch actuator

UI behaviour

None

Working conditions

Door locked, drum stop, run clutch to spin mode and drain until empty +10 seconds

more. Run clutch actuator for about 100 seconds

15.12 Drain and Spin Test

Selector position

Turn 6 clicks clockwise from the top

Purpose of the test

Verify drain system, and Pressure Sensor calibration procedure

Activated components

Door lock, main motor, drain pump

UI behaviour

None

Working conditions

Door locked, empty tub water level <5mm, if not the drain will run, if not in spin

mode the clutch actuator will run to spin position, spin up to maximum speed

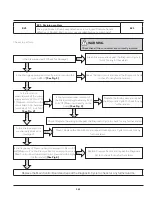

15.13 Alarm History Test

Selector position

Turn 7 clicks clockwise from the top

Purpose of the test

Communicate alarm history

Activated components

Buzzer

UI behaviour

A series of beeps separated by a short pause for one character and a long pause to

move to the second character. Press selector for next stored alarm. Example, count

12 beeps is a C

Working conditions

Drum stopped, Door unlocked

Summary of Contents for FFLE3911QW

Page 1: ...Publication 5995666392 October 2015 Technical Service Manual Laundry Center ...

Page 2: ...I ...

Page 9: ...8 3 Product Features ...

Page 14: ...13 5 1 FFLE3911QW 5 1 1 Upper Cabinet Drum Heater 5 Exploded View and List of Parts ...

Page 17: ...16 5 1 2 Motor Blower Belt ...

Page 19: ...18 5 1 3 Control Panel ...

Page 21: ...20 5 2 FFLG4033QW 5 2 1 Upper Cabinet Drum Heater ...

Page 24: ...23 5 2 2 Motor Blower Belt ...

Page 27: ...26 5 2 3 Control Panel ...

Page 32: ...31 5 3 3 Wash Assembly POS NO DESCRIPTION 14 Screw 2 PLCS 15 Lock Hub Functional parts ...

Page 33: ...32 5 3 4 Cabinet Assembly ...

Page 69: ...68 User Interface of Laundry Center FFLG4033QW ...

Page 76: ...75 8 6 Wiring Diagram FFLE3911QW Electric Dryer Model ...

Page 77: ...76 8 7 Wiring Diagram FFLG4033QW Gas Dryer Model ...

Page 78: ...77 8 8 Wiring Diagram FFLE3911QW and FFLG4033QW Washer Model ...

Page 91: ...90 Wiring Diagram FFLE3911QW Wiring Diagram FFLG4033QW ...

Page 125: ...124 ...

Page 161: ...160 ...

Page 165: ...164 ...

Page 168: ...167 ...

Page 170: ...169 ...

Page 179: ...178 ...

Page 181: ...180 ...

Page 183: ...182 ...