TORQUE CONVERTER

General Information

Page 17-2 2001 Pioneer 900 Gasoline Vehicle Maintenance and Service Manual

17

At the point of clutch engagement, the speed ratio of the drive clutch to the driven clutch is 3.5 to 1. This ratio

provides excellent starting and low-speed torque.

As engine speed increases, centrifugal force on internal weights close the drive clutch, pushing the belt up to

a higher position on the clutch (increasing the diameter of the belt loop). As the diameter of the belt loop

increases at the drive clutch, the driven clutch is forced open as the diameter of its belt loop decreases. At

governed top speed, the ratio of drive clutch to driven clutch is .92 to 1.

On steep grades, or when the vehicle is heavily loaded, higher torques are achieved through the use of a

torque-sensing ramp device on the driven clutch. This device overcomes the force of the centrifugal weights

to close the driven clutch and open the drive clutch, thus increasing axle torque with little or no change in

engine RPM.

The engine and torque converter rotate clockwise as viewed from the clutch side of the engine.

To provide optimum performance for the OHV engine and powertrain, the vehicle uses a pair of tuned

clutches.

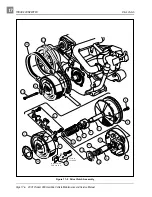

To properly assemble and disassemble the torque converter, the following tools should be used:

• Torque Converter Tool Kit (CCI 1014510) (Figure 17-1, Page 17-2).

• Scribe or small pick (not included in torque converter tool kit).

Figure 17-1 Torque Converter Tool Kit

TORQUE CONVERTER TOOL KIT

(CCI 1014510)

DRIVE

CLUTCH PULLER

(CCI 1014496)

DRIVEN CLUTCH

PULLER PLUG

(CCI 1014507)

DRIVEN CLUTCH

CAM PRESS TOOL

(CCI 101809101)

DRIVE CLUTCH HUB PULLER

(CCI 1014497)

DRIVE CLUTCH HOLDER TOOL

(CCI 1015524)

DRIVEN CLUTCH CAM PULLER

(CCI 1014508)

WARNING