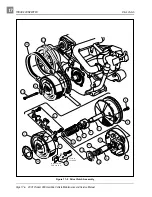

UNITIZED TRANSAXLE

Forward/Reverse (F&R) Shifter Cable

2001 Pioneer 900 Gasoline Vehicle Maintenance and Service Manual Page 16-43

16

∆ CAUTION

• Be sure threads of cable are engaged in ball joint socket at least 1/4 inch (6.35 mm). If ball joint

socket comes loose from the cable, the F&R shifter will not operate properly.

For major adjustments, the cable retaining nuts (5) must be loosened and adjusted. When the cable is prop-

erly adjusted, with the Forward/Reverse handle (21) (Figure 16-104, Page 16-42) in the NEUTRAL position,

the shift lever of the transaxle will also be in the NEUTRAL position (Figure 16-103, Page 16-41). Retighten

nuts to 22 ft-lb (29.8 N·m); retighten nuts (5) at the F&R assembly to 43 in-lb (4.9 N·m).