Chapter 1 — Basics of Firetube Operation

Part No. 750-184

1-7

D. STEAM CONTROLS (ALL FUELS)

1. Operating Limit Pressure Control (Figure 1-3): Breaks a circuit to

stop burner operation on a rise of boiler pressure at a selected

setting. It is adjusted to stop or start the burner at a preselected

pressure setting.

2. High Limit Pressure Control (Figure 1-3): Breaks a circuit to stop

burner operation on a rise of pressure above a selected setting. It

is adjusted to stop the burner at a preselected pressure above the

operating limit control setting. The high limit pressure control is

normally equipped with a manual reset.

3. Modulating Pressure Control (Figure 1-3): Senses changing boiler

pressures and transmits the information to the modulating motor

to change the burner firing rate when the manual-automatic

switch is set on “automatic.”

4. Low-Water Cutoff and Pump Control (Figure 1-4. 1-5): Float-

operated control responds to the water level in the boiler. It

performs two distinct functions:

• Stops firing of the burner if water level lowers below the safe

operating point. Energizes the low-water light in the control

panel; also causes low-water alarm bell (optional

equipment) to ring. Code requirements of some models

require a manual reset type of low-water cutoff.

• Starts and stops the feedwater pump (if used) to maintain

water at the proper operating level.

!

Caution

Determine that the main and auxiliary low water cutoffs and pump

control are level after installation and throughout the equipment’s

operating life. Failure to follow these instructions could result in

equipment damage.

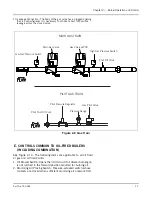

5. Water Column Assembly: Houses the low-water cutoff and pump

control and includes the water gauge glass, gauge glass shutoff

cocks.

6. Water Column Drain Valve: Provided so that the water column

and its piping can be flushed regularly to assist in maintaining

cross-connecting piping and in keeping the float bowl clean and

free of sediment. A similar drain valve is furnished with auxiliary

low-water cutoff for the same purpose.

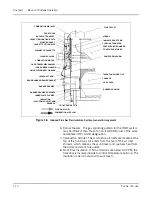

Figure 1-3 Steam Controls

Figure 1-4 CB Level Master (CB-LE

high pressure steam)

Summary of Contents for CB Ohio Special 100 HP

Page 2: ...ii ...

Page 8: ...viii ...

Page 42: ...Chapter 2 Burner Operation and Control 2 22 Part No 750 184 ...

Page 116: ...Chapter 6 Adjustment Procedures 6 28 Part No 750 184 ...

Page 126: ...Chapter 8 Inspection and Maintenance 8 6 Part No 750 184 ...

Page 153: ...Chapter 9 Parts Part No 750 184 9 3 Insulated Front Head Model CB LE ...

Page 154: ...Chapter 9 Parts 9 4 Part No 750 184 Insulated Front Head Interior Model CB LE ...

Page 155: ...Chapter 9 Parts Part No 750 184 9 5 Insulated Inner Door Model CB OS ...

Page 156: ...Chapter 9 Parts 9 6 Part No 750 184 Insulated Rear Head CB LE ...

Page 157: ...Chapter 9 Parts Part No 750 184 9 7 Insulated Rear Head CB LE ...

Page 158: ...Chapter 9 Parts 9 8 Part No 750 184 Insulated Rear Head CB OS ...

Page 159: ...Chapter 9 Parts Part No 750 184 9 9 Dry Oven Model CB LE ...

Page 161: ...Chapter 9 Parts Part No 750 184 9 11 Motor Impeller Model CB LE ...

Page 162: ...Chapter 9 Parts 9 12 Part No 750 184 Front Head Linkage ...

Page 170: ...Chapter 9 Parts 9 20 Part No 750 184 Control Cabinet Hawk ICS ...

Page 171: ...Chapter 9 Parts Part No 750 184 9 21 Control Panel Standard ...

Page 172: ...Chapter 9 Parts 9 22 Part No 750 184 Entrance Box ...

Page 173: ...Chapter 9 Parts Part No 750 184 9 23 Front Head Electrical CB LE ...

Page 174: ...Chapter 9 Parts 9 24 Part No 750 184 Front Head Electrical CB LE ...

Page 175: ...Chapter 9 Parts Part No 750 184 9 25 Front Head Electrical CB OS ...

Page 176: ...Chapter 9 Parts 9 26 Part No 750 184 Front Head Electrical CB OS ...

Page 179: ...Chapter 9 Parts Part No 750 184 9 29 Heavy Oil Piping 60 Steam CB LE ...

Page 180: ...Chapter 9 Parts 9 30 Part No 750 184 Heavy Oil Piping 60 Steam CB LE SEE TABLE NEXT PAGE ...

Page 181: ...Chapter 9 Parts Part No 750 184 9 31 Common Oil Parts Heavy Oil ...

Page 182: ...Chapter 9 Parts 9 32 Part No 750 184 Side Mounted Air Compressor Piping ...

Page 183: ...Chapter 9 Parts Part No 750 184 9 33 Air Compressor Piping CB OS ...

Page 185: ...Chapter 9 Parts Part No 750 184 9 35 Light Oil Piping ...

Page 186: ...Chapter 9 Parts 9 36 Part No 750 184 Light Oil Air Piping Front Head ...

Page 187: ...Chapter 9 Parts Part No 750 184 9 37 Light Oil Air Piping Front Head PAGE 9 31 ...

Page 191: ...Chapter 9 Parts Part No 750 184 9 41 Gas Train 125 150 HP ...

Page 193: ...Chapter 9 Parts Part No 750 184 9 43 Gas Train 200 HP ...

Page 195: ...Chapter 9 Parts Part No 750 184 9 45 Steam Pressure Controls ...

Page 196: ...Chapter 9 Parts 9 46 Part No 750 184 Hot Water Temperature Controls ...

Page 197: ...Chapter 9 Parts Part No 750 184 9 47 Water Column ...

Page 198: ...Chapter 9 Parts 9 48 Part No 750 184 Water Column ...

Page 199: ...Chapter 9 Parts Part No 750 184 9 49 Fireside Gaskets CB LE ...

Page 200: ...Chapter 9 Parts 9 50 Part No 750 184 Fireside Gaskets CB OS ...