Chapter 3 — Waterside Care and Requirements

3-2

Part No. 750-184

A. GENERAL

The operator should be familiar with Chapter 3 before attempting to

place the unit into operation.

Although it is of prime importance, the subject of water supply and

treatment cannot adequately be covered in this manual. For specific

information or assistance with your water treatment requirements,

contact your Cleaver-Brooks service and parts representative.

Feedwater equipment should be checked and ready for use. Be sure

that all valves, piping, boiler feed pumps, and receivers are installed

in accordance with prevailing codes and practices.

Water requirements for both steam and hot water boilers are

essential to boiler life and length of service. It is vital that care be

taken in placing the pressure vessel into initial service. The

waterside of new boilers and new or remodeled steam or hot water

systems may contain oil, grease or other foreign matter. A method

of boiling out the vessel to remove the accumulations is described

later in Chapter 3.

Boilers, as a part of a hot water system, require proper water

circulation. The system must be operated as intended by its

designer in order to avoid thermal shock or severe, possibly

damaging, stresses from occurring to the pressure vessel.

Note: This manual only covers boilers using water. Glycol solutions

have different operating requirements, circulation rates and

temperatures, etc.

B. WATER REQUIREMENTS

1. HOT WATER BOILER

Air Removal

The hot water outlet includes a dip tube which extends 2 to 3 inches

into the boiler. The dip tube reduces the possibility of air, which may

be trapped at the top of the shell, from entering into the system.

Oxygen or air released in the boiler will collect or be trapped at the

top of the boiler shell.

The air vent tapping on the top center line of the boiler should be

piped into the expansion or compression tank. Air trapped at the top

of the boiler will find its way out of the boiler through the tapping.

Minimum Water Temperature -

The minimum recommended boiler

water temperature is 170

°

F. When water temperatures lower than

170

°

F are used, the combustion gases are reduced in temperature

to a point where water vapor condenses, causing corrosion in the

boiler and possible breeching.

Condensation is more severe on a unit that operates intermittently

and which is greatly oversized for the actual load. Condensation can

be minimized by maintaining boiler water temperatures above

170

°

F.

Summary of Contents for CB Ohio Special 100 HP

Page 2: ...ii ...

Page 8: ...viii ...

Page 42: ...Chapter 2 Burner Operation and Control 2 22 Part No 750 184 ...

Page 116: ...Chapter 6 Adjustment Procedures 6 28 Part No 750 184 ...

Page 126: ...Chapter 8 Inspection and Maintenance 8 6 Part No 750 184 ...

Page 153: ...Chapter 9 Parts Part No 750 184 9 3 Insulated Front Head Model CB LE ...

Page 154: ...Chapter 9 Parts 9 4 Part No 750 184 Insulated Front Head Interior Model CB LE ...

Page 155: ...Chapter 9 Parts Part No 750 184 9 5 Insulated Inner Door Model CB OS ...

Page 156: ...Chapter 9 Parts 9 6 Part No 750 184 Insulated Rear Head CB LE ...

Page 157: ...Chapter 9 Parts Part No 750 184 9 7 Insulated Rear Head CB LE ...

Page 158: ...Chapter 9 Parts 9 8 Part No 750 184 Insulated Rear Head CB OS ...

Page 159: ...Chapter 9 Parts Part No 750 184 9 9 Dry Oven Model CB LE ...

Page 161: ...Chapter 9 Parts Part No 750 184 9 11 Motor Impeller Model CB LE ...

Page 162: ...Chapter 9 Parts 9 12 Part No 750 184 Front Head Linkage ...

Page 170: ...Chapter 9 Parts 9 20 Part No 750 184 Control Cabinet Hawk ICS ...

Page 171: ...Chapter 9 Parts Part No 750 184 9 21 Control Panel Standard ...

Page 172: ...Chapter 9 Parts 9 22 Part No 750 184 Entrance Box ...

Page 173: ...Chapter 9 Parts Part No 750 184 9 23 Front Head Electrical CB LE ...

Page 174: ...Chapter 9 Parts 9 24 Part No 750 184 Front Head Electrical CB LE ...

Page 175: ...Chapter 9 Parts Part No 750 184 9 25 Front Head Electrical CB OS ...

Page 176: ...Chapter 9 Parts 9 26 Part No 750 184 Front Head Electrical CB OS ...

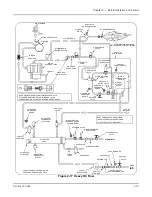

Page 179: ...Chapter 9 Parts Part No 750 184 9 29 Heavy Oil Piping 60 Steam CB LE ...

Page 180: ...Chapter 9 Parts 9 30 Part No 750 184 Heavy Oil Piping 60 Steam CB LE SEE TABLE NEXT PAGE ...

Page 181: ...Chapter 9 Parts Part No 750 184 9 31 Common Oil Parts Heavy Oil ...

Page 182: ...Chapter 9 Parts 9 32 Part No 750 184 Side Mounted Air Compressor Piping ...

Page 183: ...Chapter 9 Parts Part No 750 184 9 33 Air Compressor Piping CB OS ...

Page 185: ...Chapter 9 Parts Part No 750 184 9 35 Light Oil Piping ...

Page 186: ...Chapter 9 Parts 9 36 Part No 750 184 Light Oil Air Piping Front Head ...

Page 187: ...Chapter 9 Parts Part No 750 184 9 37 Light Oil Air Piping Front Head PAGE 9 31 ...

Page 191: ...Chapter 9 Parts Part No 750 184 9 41 Gas Train 125 150 HP ...

Page 193: ...Chapter 9 Parts Part No 750 184 9 43 Gas Train 200 HP ...

Page 195: ...Chapter 9 Parts Part No 750 184 9 45 Steam Pressure Controls ...

Page 196: ...Chapter 9 Parts 9 46 Part No 750 184 Hot Water Temperature Controls ...

Page 197: ...Chapter 9 Parts Part No 750 184 9 47 Water Column ...

Page 198: ...Chapter 9 Parts 9 48 Part No 750 184 Water Column ...

Page 199: ...Chapter 9 Parts Part No 750 184 9 49 Fireside Gaskets CB LE ...

Page 200: ...Chapter 9 Parts 9 50 Part No 750 184 Fireside Gaskets CB OS ...