1 689 989 000

2013-05-02

|

Robert Bosch GmbH

44 | EPS 200 | Maintenance

en

6.2.5

Replacing the test oil

!

Before replacing the test oil, the EPS 200 must be

turned off and disconnected from the power supply.

!

During use, the test oil is subject to the effects of

evaporation, temperature, pressure, oxidation and

the impact of foreign matter. Regular checking is

therefore essential to ensure compliance with the

necessary test oil quality standard when checking

nozzle-and-holder assemblies and injectors. The

test oil must always be replaced if it is considerably

darker than in the as-new condition. Contaminated

test oil can result in biased measured values and

damage both the EPS 200 and injectors/nozzle-and-

holder assemblies during testing.

Authorized types of test oil:

Oil type

Manufacturer

SHELL Calibration Fluid S 9365

Shell International

SHELL V-OIL 1404

Shell Germany

SHELL Normafluid B. R.

SHELL France

VISCOR

Calibration Fluid 1487 AW-2

Rock Vallery

CASTROL

fluido para Calibracao 4113

Castrol Brazil

ESSO EGL 70 147

Esso AG

BENZ UCF-1 Calibration Fluid

Benz Oil

DIVINOL Calibration Fluid 2928V3

Gmelin GmbH &

Co. KG

Procedure:

1.

Turn off the EPS 200.

2.

Disconnect the EPS 200 from the power supply.

3.

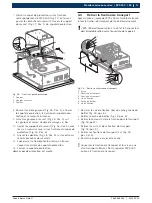

Unscrew the fastening screws (8x) on the left of the

housing cover (Fig. 22, Pos. 6).

4.

Remove housing cover (Fig. 22, Pos. 5).

5.

Unscrew the ground lead on the side panel of the

housing (Fig. 22, Pos. 7).

!

As soon as the quick release coupling is attached

to the EPS 200, test oil flows through the hose

line. Always place the end of the hose line in the oil

collecting tank first.

6.

Place the end of the 1.5 m hose line (Fig. 22, Pos. 4;

1 680 712 283) without the quick release coupling in

the oil collecting tank (Fig. 22, Pos. 3).

7.

Insert the 1.5 m hose line (1 680 712 283) with quick

release coupling into the quick release coupling on

the test oil tank (Fig. 22, Pos. 1).

Test oil flows into the oil collecting tank.

EPS 20

0

1l

BOSCH

458822-4

5

6

2

1

3

7

4

X20

8

Fig. 22: Draining the test oil

1 Test oil tank quick-release coupling

2 Settling chamber quick-release coupling

3 Oil collector

4 Hose

5 Housing cover

6 Fastening screws

7 Ground wire

8 Oil cooler quick-release coupling

8.

Once the test oil has drained out of the test oil tank,

insert the hose line into the quick release coupling

on the settling chamber (Fig. 22, Pos. 2).

Test oil flows from the settling chamber into the

oil collecting tank.

9.

Once the test oil has drained out of the settling

chamber, insert the hose line into the quick release

coupling on the oil cooler (Fig. 22, Pos. 8).

Test oil flows from the oil cooler into the oil

collecting tank.

10.

Once the test oil has drained out of the oil cooler,

disconnect the hose line from the quick release

coupling.

11.

Use a clean cloth to clean the test oil tank.

12.

Screw the ground lead onto the housing cover.

13.

Replace the housing cover and screw into place.

!

If the test oil is added too quickly, it is possible that it

will run out of the upward facing flushing outlet or the

connection for the external extractor (Fig. 1, Pos. 5).

14.

Pour the new test oil (ISO 4113) into the jet cham-

ber (Fig. 3, Pos. 2) very slowly and carefully. The

test oil tank holds around 6.5 liters.

15.

Add test oil until it reaches the upper marking in

the oil level display (Fig. 1, Pos. 9).

"

Replacement of the test oil is complete.