1 689 989 000

2013-05-02

|

Robert Bosch GmbH

34 | EPS 200 | Product description

en

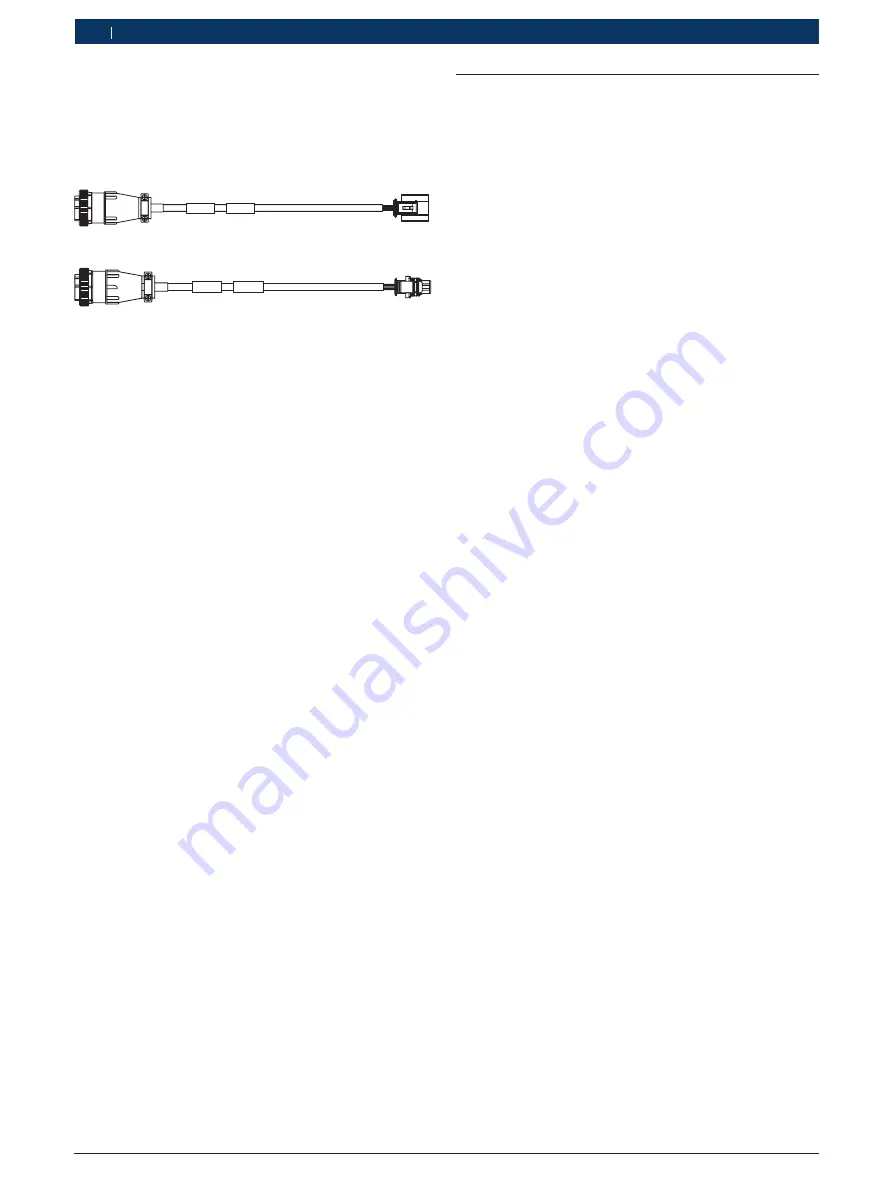

3.5.11 Adapter leads for CRI connection

The adapter leads supplied (1 684 465 574 and

1 684 465 575) are required to allow actuation of the

CRI solenoid valve using the EPS 200. These adapter

leads are primarily used for Bosch CRIs.

1 684 465 574

458822-73

Fig. 12: Fig. 12 Adapter lead 1 684 465 574

1 684 465 575

458822-74

Fig. 13: Fig. 13 Adapter lead 1 684 465 575

i

Other adapter leads are available as optional

accessories for the various non-Bosch CRIs and for

Bosch CRINs.

3.5.12 Oil drain hose line

The oil drain hose line supplied (1 680 712 283) is required

to drain the test oil tank (see Maintenance section).

3.5.13 Sealing plug for leak test

The sealing plug supplied is required to perform the

daily leak test. The sealing plug has two threads

(M12 and M14) and is screwed onto the relevant

connection adapter.

!

The sealing plug must be tightened to a torque of

between 25 Nm and 30 Nm.

3.5.14 Protective cover

All tests on a DHK/UI or CRI/CRIN can only be

performed with the cover closed. If the cover is opened

during the test, the test is terminated immediately and

must be re-started.

3.6

Description of function

The EPS 200 is designed as a compact unit. It contains

all components needed for testing a CRI/CRIN

and DHK/UI, e.g. high pressure pump for pressure

generation, test oil tank, flow meter, measuring circuit

board, computer circuit board and LCD display with

touchscreen. To build up the pressure necessary for

testing, a high pressure pump and a high pressure rail

are used. The high pressure pump conveys the test oil,

while the high pressure rail with a pressure control

valve controls the pressure required for testing. The

DHK/UI and CRI/CRIN are connected using a high

pressure connecting line and a connection adapter.

In addition, the CRI/CRIN is actuated by an electric

adapter lead.

The tests on a CRI/CRIN and DHK/UI can only be

performed with the protective cover closed. The

protective cover’s emergency shutdown function aborts

the testing process as soon as the protective cover is

opened and reduces the test oil pressure to < 80 MPa.

The integral two-chamber test oil tank has a capacity of

around seven liters. Coarse impurities are collected in

the first chamber. In the second chamber, the test oil is

brought to the correct testing temperature. The EPS 200

system software can be used to test the most important

functions on the DHK/UI, such as opening pressure

1 and 2, vibration control, combination tightness, seat

tightness and the jet pattern. The illumination in the jet

chamber allows the DHK/UI’s jet pattern to be assessed.

When testing the jet pattern on a DHK/UI, the air flow

controller for the internal extractor (Fig. 1, Pos. 8) is

used to ensure that at little test oil vapor as possible

can escape. A leak test is performed on the CRI/CRIN

and the injection quantity and return quantity can be

measured at full load and when idle.