e. Collect empty sample tube carriers for the tubes collected from loading racks. Or

manual load the rack into the DxH Input buffer and run the tubes. When the rack is

unloaded transfer it from the DxH manual unload area to the upper unload shuttle

position

f. Select

Auto

and

OK

to place the module back into operation. Allow the

system to load any tubes at BR01 and BR02 into the loading rack.

g. Place the tubes that you removed from the loading areas into the extra sample tube

carriers and manually load them into the loading queues at SN004 and SN006.

h. Place the removed unloading racks into the upper unload shuttle position.

i. Place any empty racks into the upper unload shuttle position.

18

At the DxC Rack Builder modules:

a. Let the instrument(s) continue to run and process samples.

b. If sample tubes are in the quadruple-gripper transfer arm or the single gripper arm

at the DxC instrument console, verify that samples are completed.

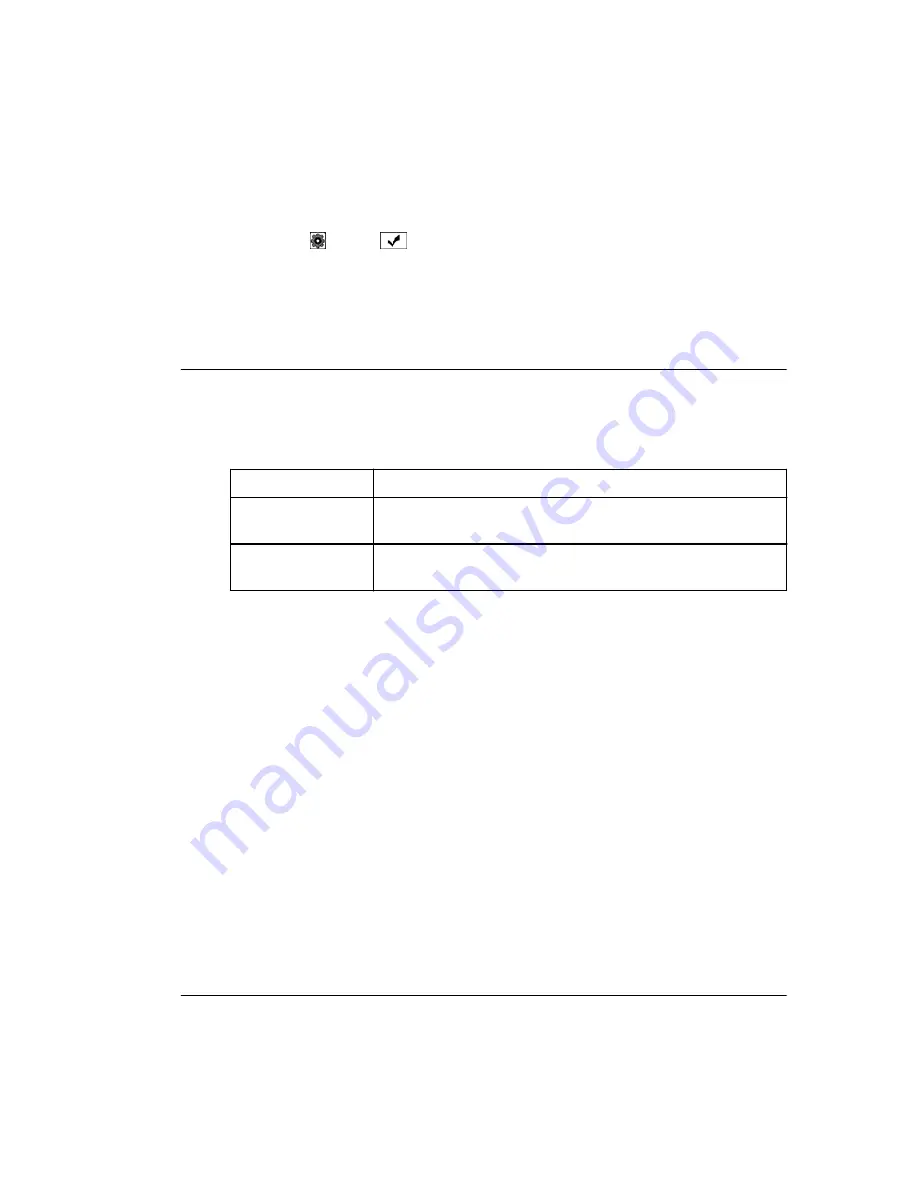

If...

Then...

samples are

completed,

Transfer these tubes to the sample tube carriers that are waiting to be

unloaded at the Connection Module.

samples are not

completed,

Transfer these tubes to an offline instrument rack in the output tray

on the right side of the instrument.

c. Remove any sample tubes from the racks in the DxC instrument load tray. Transfer

these tubes to another rack(s) and put this rack(s) in the output tray on the right

side of the instrument(s).

d. Remove sample tubes from the instrument load shuttle. Place these tubes into

another rack and place this rack in the output tray on the right side of the

instrument. Remove any tubes in the instrument unload shuttle and place in the

sample tube carriers at the unload position.

e. After placing the completed tubes into the sample tube carriers at the unload

position, place the DxC Connector unit into Function mode

96

. When the carriers

with sample tubes have completely left the unload position, place the DxC

Connector unit into Run.

f. Process the racks collected in the right side output tray using the Analyzer's

PRIORITY

button. Load racks into the left side Input tray of the DxC and Press the

Run

button. Process a maximum of 2 racks at a time to allow the automation system

to continue loading racks onto the DxC instrument once the track is re-started.

g. As samples are completed and unloaded to the right hand side of the DxC, place the

Connector unit back into Function mode

96

and transfer these tubes to the sample

tube carriers that are waiting for unloading at the Connection Module. When the

carriers with sample tubes have completely left the unload position, place the DxC

Connector unit back into

Run

.

19

At the Direct Track Sampling modules (excluding Abbott i2000SR):

a. If a stopper is jamming the sample tube carrier, push it forward to release the

carrier.

Error Recovery Procedures

Power Express Aliquot Error Recovery Procedures

3-12

B31449AE

Summary of Contents for Power Express Aliquot

Page 6: ...Warranty and Service vi B31449AE...

Page 22: ...Introduction Scope of this Manual xxii B31449AE...

Page 30: ...Power Express Aliquot Module Description Components 1 8 B31449AE...

Page 110: ...Figure 4 3 Tube Supply Sensor Diagram 4 50 B31449AE Troubleshooting...

Page 111: ...Figure 4 4 Label Supply Sensor Diagram B31449AE 4 51 Troubleshooting...

Page 112: ...Aliquot Unit Figure 4 5 Overview Sensor Diagram 4 52 B31449AE Troubleshooting...

Page 114: ...Figure 4 7 Tip Supply Sensor Diagram 4 54 B31449AE Troubleshooting...

Page 117: ...Figure 4 10 Optional Track Sensor Diagram B31449AE 4 57 Troubleshooting...

Page 118: ...Figure 4 11 Merge Lane Sensor Diagram 4 58 B31449AE Troubleshooting...

Page 120: ...Related Documents Related Documents A 2 B31449AE...

Page 121: ......

Page 122: ...www beckmancoulter com 2018 Beckman Coulter Inc All Rights Reserved...