Scratch Testing E

Agilent Nano Indenter G200 User’s Guide

E-13

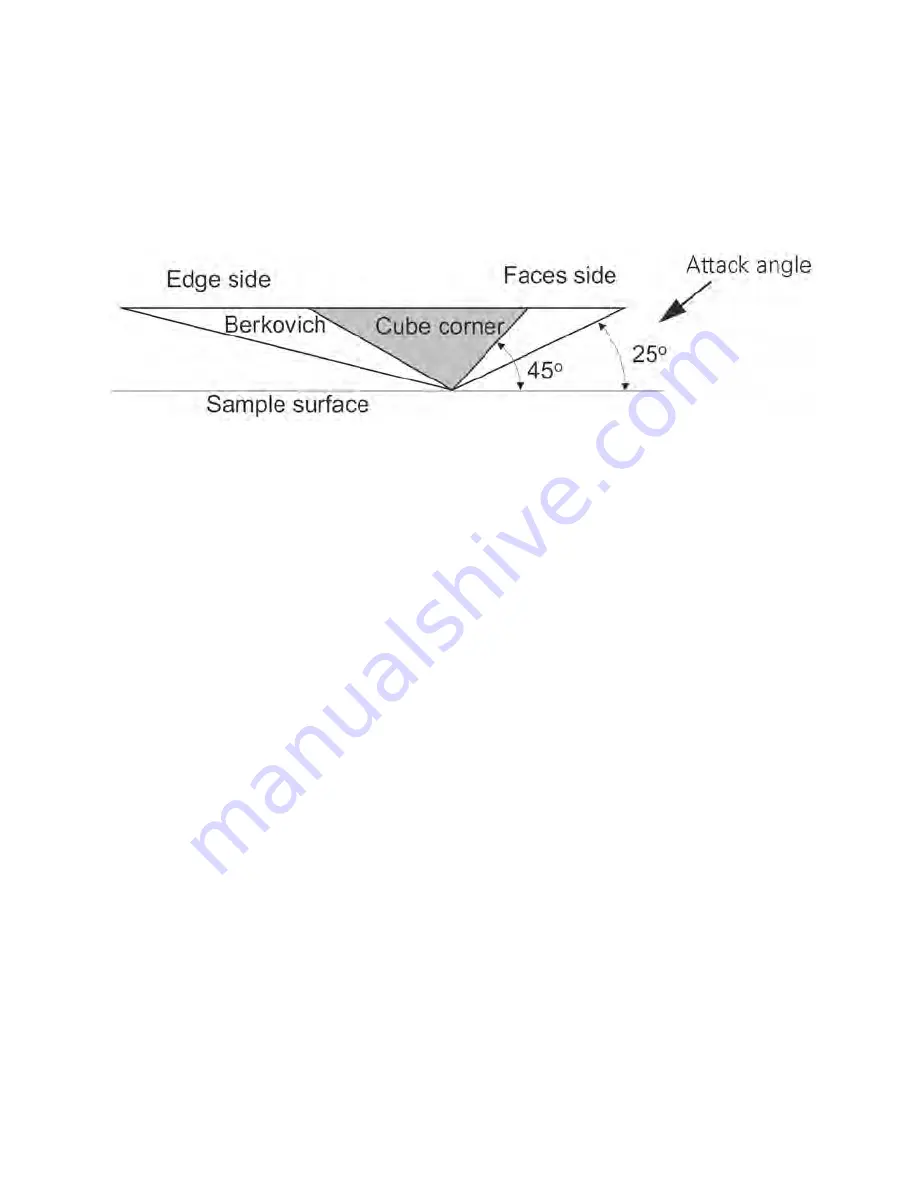

The fracture is usually related to the severity of the contact, mostly

related to the attack angle of the indenter, which is the angle between the

indenter face and the sample surface, as shown in

Figure E-9

Attack angle comparison between Berkovich vs cube corner

indenter

An indenter tip is usually blunted at its extremity, so under light loads

the contact may not create any fracture process, while under higher

loads, fracture will occur. For instance, some materials may never crack

if scratched with a Berkovich, under any loads, but would crack very

easily using a cube corner indenter, which has a higher attack angle.

Influence of Indenter Geometry

The indenter geometry used during a scratch has a great influence on the

surface behavior. Therefore, a description of the indenter geometry

should be included with the test results.

Various indenter shapes may be used for scratch testing, and each of

them has advantages and drawbacks. The following list is not

exhaustive: conical indenters with spherical tip, pyramids, spheres,

Berkovich, and cube corner.

Indenter geometry has a strong effect on elastic-plastic deformation

morphology.

on page E-14 illustrates the effect of the

orientation of a Berkovich indenter on the residual scratch morphology

(for scratches performed under the same normal load and at the same

velocity). The pile-up formation is much less evident when the edge of

the Berkovich indenter is oriented in the scratch direction. It is

interesting to note that in this example, the indenter penetration depth

did not strongly depend on its orientation.