ENGINE

4-35

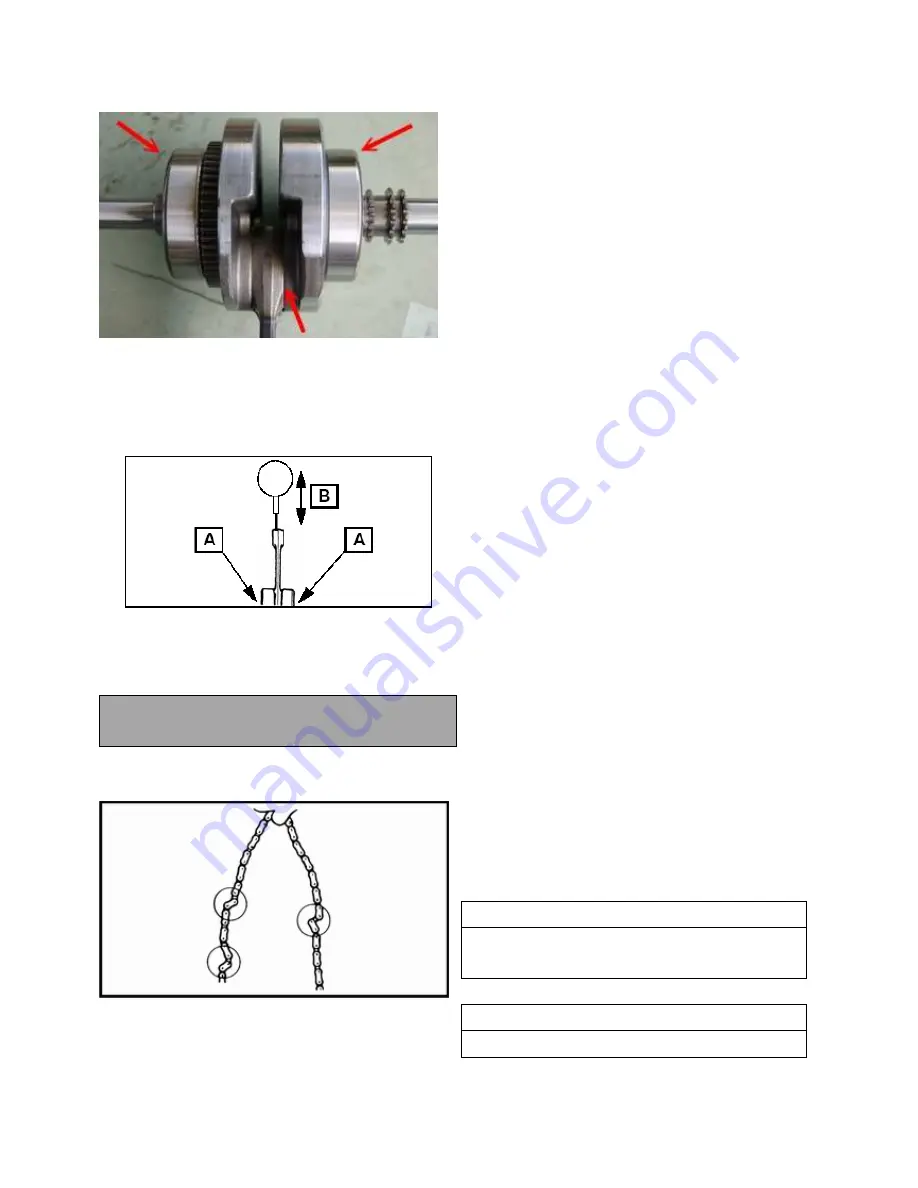

3. The connecting rod utilizes a roller bearing. Clearance is

minimal and cannot be measured. Visually inspect bearing

journal for scoring, damage or excessive wear. Replace

crankshaft if it fails visual inspection.

CRANKCASE / BEARING INSPECTION

NOTE: Removal and installation of new seals is

recommended anytime the crankcase is

disassembled.

1. Inspect the bearings in the crankcase.

NOTE: Due to extremely close tolerances and

minimal side wear, the bearing must be inspected

visually and by feel. Look for signs of discoloration,

scoring or galling. Turn the inner race of bearing. The

bearing should turn smoothly and quietly. The outer

race should fit tightly in the crankcase. The inner

race should be firm with minimal side-to-side

movement and no detectable up and down

movement.

2. To remove crankcase bearings, use a blind hole bearing

puller.

NOTE: Bearings are stressed during the removal

procedure and should not be re-used.

3. Remove all traces of gasket sealer from the crankcase

mating surfaces. Inspect the surfaces closely for nicks, burrs or

damage.

CRANKCASE OIL STRAINER INSPECTION

1. Remove drain plug.

2. Remove oil strainer and visually inspect for any rips, tears

or obstructions in screen.

3. Replace oil strainer if it fails visual inspection.

BEARING /SEAL INSTALLATION

NOTE: To ease crankcase-bearing installation, warm

the crankcase until hot to the touch. Placing the

bearing in a freezer prior to installation will assist the

assembly process.

1. Install the bearing so the numbers are visible.

2. Drive or press the new bearing into the crankcase, using the

proper driver.

CAUTION

Press only on outer race of bearing to prevent

bearing damage.

3. Install new seals with the lip facing in.

CAUTION

Press only on outer diameter to prevent damage.

4. Inspect the clearance of connecting rod big end and flywheel

by feeling gauge. If clearance is excessive replace the

crankshaft assembly.

CONNECTING ROD CLEARANCE LIMITATION:

0.5 mm

5. Inspect chain for worn or missing rollers or damage.

Replace if worn excessively or as part of any crankshaft repair.

Summary of Contents for AT56-69E

Page 35: ...MAINTENANCE 2 25 ...

Page 45: ...CVT SYSTEM 3 4 CVT EXPLODED VIEW ...

Page 56: ...ENGINE 4 3 ENGINE ILLUSTRATION ENGINE EXPLODED VIEW ...

Page 57: ...ENGINE 4 4 ...

Page 58: ...ENGINE 4 5 COOLING SYSTEM EXPLODED VIEW ...

Page 59: ...ENGINE 4 6 OIL FLOW DIAGRAM ...

Page 125: ...FUEL AND CARBURETOR 6 15 FUEL TANK SYSTEM ...

Page 135: ...BODY SUSPENSION STEERING 7 6 SUSPENSION ...

Page 142: ...BODY SUSPENSION STEERING 7 13 STEERING ...

Page 151: ...BRAKES 8 6 FRONT BRAKE EXPLODED VIEW MASTER CYLINDER ...

Page 196: ...ELECTRICAL 9 31 WIRE DIAGRAM ...