ENGINE

4-20

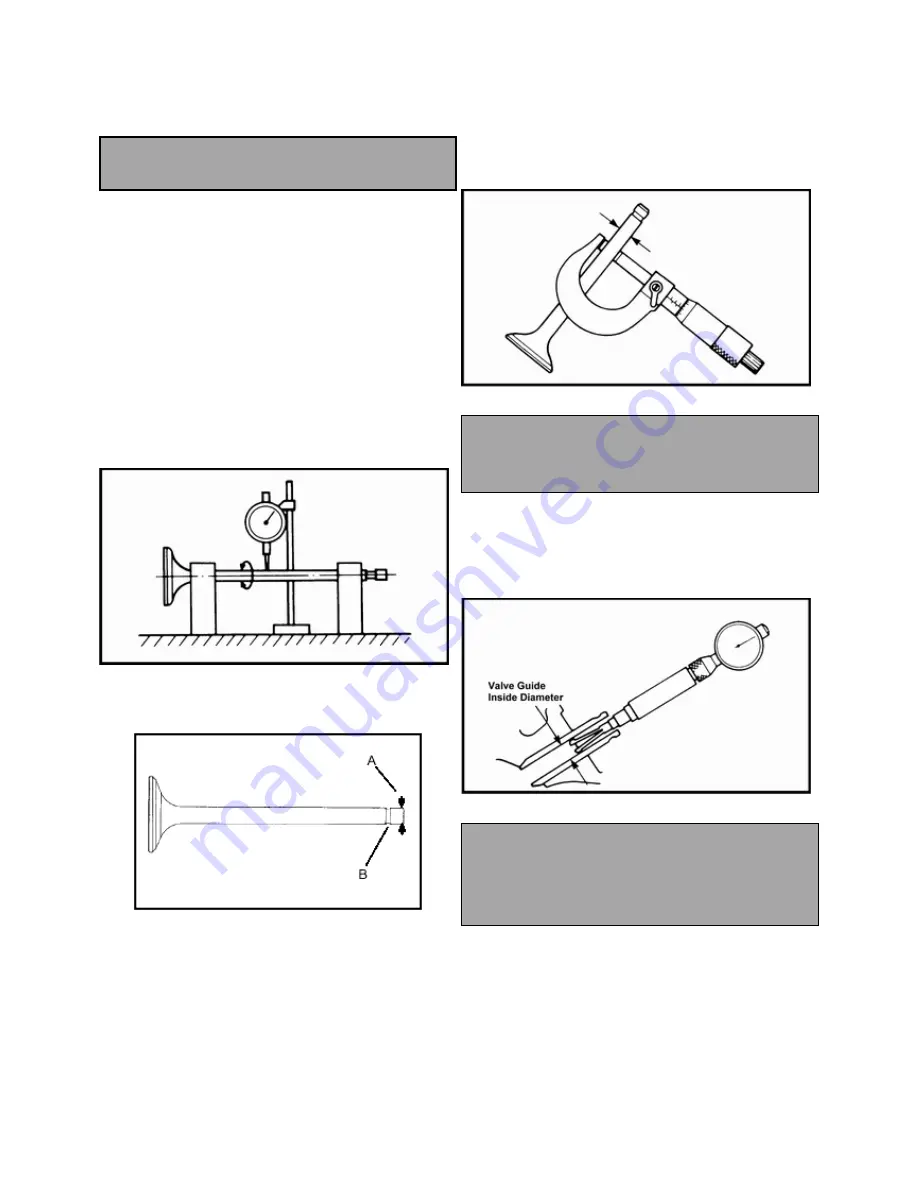

VALVE SPRING VERTICALITY

Service Limit: 1.6mm

NOTE: Replace seals whenever the cylinder head is

disassembled. Hardened, cracked or worn valve

seals will cause excessive oil consumption and

carbon buildup.

VALVE INSPECTION

1. Remove all carbon from valve with a soft wire wheel.

2. Check valve face for run out, pitting, and burnt spots. To

check for bent valve stems, mount valve in a drill or use “V”

blocks and a dial indicator.

3. Check end of valve stem for flaring, pitting, wear or damage

(A).

4. Inspect split keeper groove for wear or flaring of the keeper

seat area (B).

NOTE: The valves cannot be re-faced or end ground.

They must be replaced if worn, bent, or damaged.

5. Measure diameter of valve stem with a micrometer in three

places and in two different directions (six measurements total).

Replace if excessive wear is evident.

VALVE STEM OUTER-DIAMETER LIMITATION

Intake Valve Limit: 5.4mm

Exhaust Valve Limit: 5.4mm

6. Measure valve guide inside diameter at the top middle and

end of the guide using a small orifice gauge and a micrometer.

Measure in two directions, front to back and side to side.

CLEARANCE (STEM TO GUIDE) SERVICE

LIMITATION

Intake: 0.10mm

Exhaust: 0.10mm

7. Subtract valve stem measurement to obtain stem to guide

clearance.

Summary of Contents for AT56-69E

Page 35: ...MAINTENANCE 2 25 ...

Page 45: ...CVT SYSTEM 3 4 CVT EXPLODED VIEW ...

Page 56: ...ENGINE 4 3 ENGINE ILLUSTRATION ENGINE EXPLODED VIEW ...

Page 57: ...ENGINE 4 4 ...

Page 58: ...ENGINE 4 5 COOLING SYSTEM EXPLODED VIEW ...

Page 59: ...ENGINE 4 6 OIL FLOW DIAGRAM ...

Page 125: ...FUEL AND CARBURETOR 6 15 FUEL TANK SYSTEM ...

Page 135: ...BODY SUSPENSION STEERING 7 6 SUSPENSION ...

Page 142: ...BODY SUSPENSION STEERING 7 13 STEERING ...

Page 151: ...BRAKES 8 6 FRONT BRAKE EXPLODED VIEW MASTER CYLINDER ...

Page 196: ...ELECTRICAL 9 31 WIRE DIAGRAM ...