ENGINE

4-18

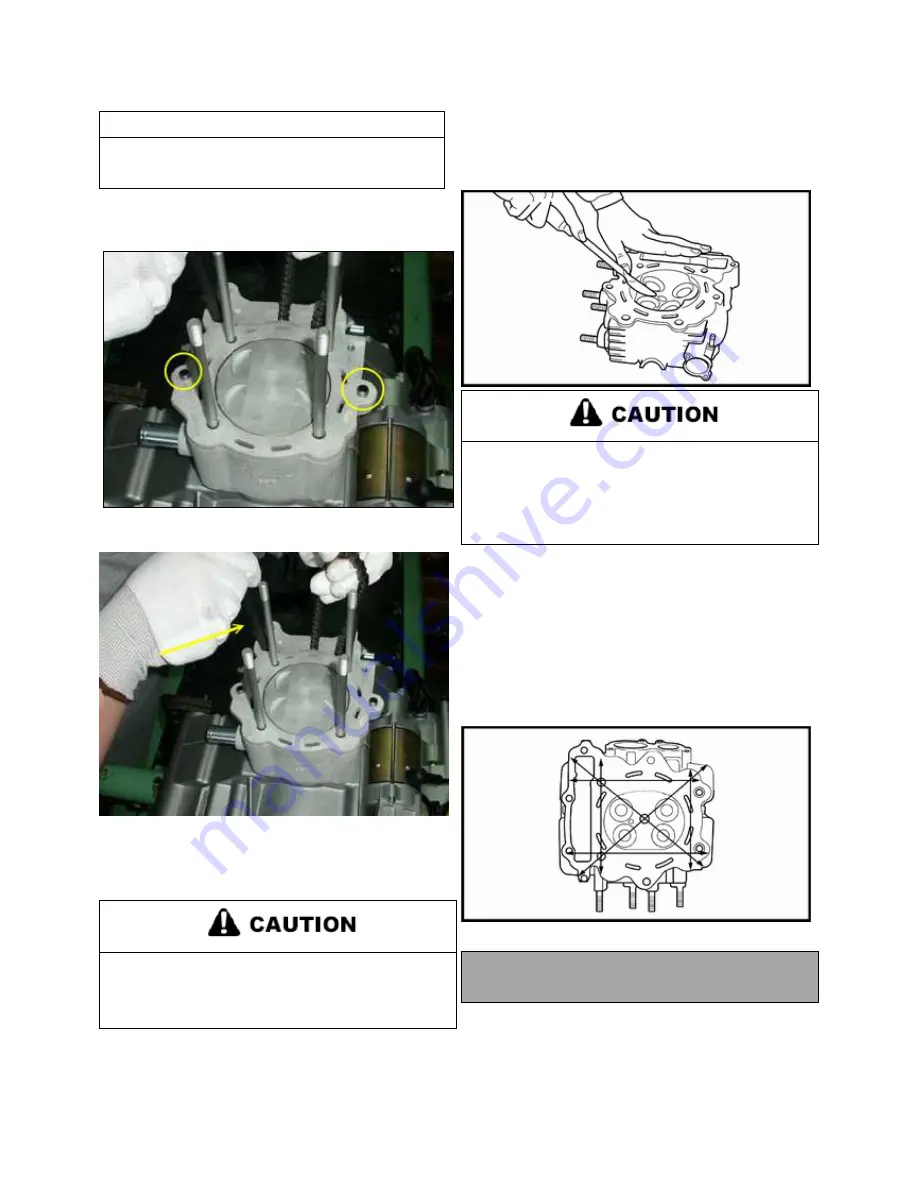

CAUTION

Tap only in reinforced areas or on thick parts of

cylinder head casting to avoid damaging casting.

10. Remove cylinder head gasket and 2-dowel pins.

11. Remove chain guide.

12.

Clean up residues from the matching surfaces of cylinder

and cylinder head.

Use care not to damage sealing surface.

Avoid residues of gasket or foreign materials falling

into crankcase while cleaning.

CYLINDER HEAD INSPECTION

1. Thoroughly clean cylinder head surface to remove all traces

of gasket material and carbon.

Use care not to damage sealing surface. If there is

damage found on the cylinder head combustion

chamber, it is recommended the component be

replaced.

CYLINDER HEAD WARP INSPECTION

1. Lay a straight edge across the surface of the head at several

different points and measure warp age by inserting a feeler

gauge between the straight edge and the cylinder head surface.

If warp age exceeds the service limit, replace the cylinder

head.

WARP LIMITATION:

0.05mm

Summary of Contents for AT56-69E

Page 35: ...MAINTENANCE 2 25 ...

Page 45: ...CVT SYSTEM 3 4 CVT EXPLODED VIEW ...

Page 56: ...ENGINE 4 3 ENGINE ILLUSTRATION ENGINE EXPLODED VIEW ...

Page 57: ...ENGINE 4 4 ...

Page 58: ...ENGINE 4 5 COOLING SYSTEM EXPLODED VIEW ...

Page 59: ...ENGINE 4 6 OIL FLOW DIAGRAM ...

Page 125: ...FUEL AND CARBURETOR 6 15 FUEL TANK SYSTEM ...

Page 135: ...BODY SUSPENSION STEERING 7 6 SUSPENSION ...

Page 142: ...BODY SUSPENSION STEERING 7 13 STEERING ...

Page 151: ...BRAKES 8 6 FRONT BRAKE EXPLODED VIEW MASTER CYLINDER ...

Page 196: ...ELECTRICAL 9 31 WIRE DIAGRAM ...