Page 2–30

2101510 Rev. AG

2.14.1 Location

•

Locate the pipeline coupling on the gas meter run in close proximity to the

NGC. This allows the stainless steel sample line from sample probe to

Chromatograph to be as short as possible.

•

The coupling should be mounted so the probe can be installed horizontally or

vertically on the meter run pipe. This means the coupling should be mounted

on either the top or the side of the meter run pipe.

•

Sample probe should not be mounted at the ends of headers, dead T’s, large

volume accumulators or other spots where gas is likely to be stagnant.

•

Installation should allow the probe to penetrate the center 1/3 of the main gas

meter run. This allows sufficient heat transfer with the flowing gas sample.

Sample probe inlet should be high enough to avoid sampling of liquids at the

bottom of the pipe.

•

The sample probe must be installed where the probe has access to the

fastest flow of gas within the pipe.

•

The sample probe should be mounted a minimum of five pipe diameters from

any device which could cause aerosols or significant pressure drops.

2.14.2 Other Considerations

•

TCR sample probe line pressure should be as close to 1-atmosphere as

possible to reduce sample transport lag times due to line pack. Sample

pressure at the NGC should be 15

±

2 psig (103

±

14 Kpa).

•

To maintain this pressure at the NGC filters, it may be necessary to increase

TCR sample probe pressure to a value greater than 15 psig. Pressure is

dependent on sample transport tubing length between the TCR sample probe

and analyzer.

•

Be sure to use tubing electrical isolators on sample tubing when connected to

pipelines that are not isolated from cathodic protection.

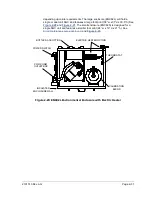

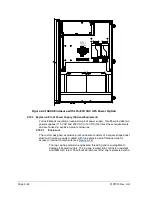

2.15 Environmental Enclosure (Optional Equipment)

In colder climates (ambient temperatures 0 °F to -40 °F) this environmental

enclosure (ENC82) allows mounting of the NGC directly on the pipe. This

insulated weatherproof enclosure has brackets for the NGC and a small start

up/calibration bottle. Having the calibration bottle in the heated enclosure ensures

a much more stable and consistent calibration.

2.15.1 Standard Features

•

Available with either an electric or catalytic heater option:

o

The catalytic heater is a 1500 Btu/hour input, and includes a standard

filter/drain kit.

o

The electric heater option features 120 VAC/400 W heater and

thermostat.

•

Sample conditioning system

•

Heated line entry

•

Rigid conduit

•

Mounts either as a free-standing unit or pipe mounted unit:

o

Large enclosure may be pipe-mounted on 4” through 12” pipe.

o

Small enclosure may be pipe-mounted on 2” through 5” pipe.

2.15.1.1

Enclosure

The heater and enclosure is designed to maintain a 40 °F inside temperature

when outside temperature is -40 °F. Two enclosures are available for installation