Page 2–24

2101510 Rev. AG

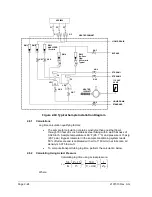

Figure 2-18 Typical Sample Installation Diagram

2.8.1

Calculations

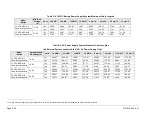

Lag time calculation qualifying factors:

•

The sample for calculation contains mostly methane gas that flows

through 100 feet of ¼-inch stainless steel tubing with a wall thickness of

0.020-inch. Sample temperature is 80

°

F (26.7

°

C) and pressure is 15 psig

(29.7 psia). Bypass rotameter in the sample conditioning system reads

50% of full scale and is calibrated with air to 1180 cc/min at full scale. Air

density is 0.075 lbs/cu.ft.

•

To compute transport tubing lag time, perform the calculation below.

2.8.2

Calculating Using Actual Pressure

Calculating lag time using actual pressure:

×

+

×

+

=

p

s

Z

1

460

T

530

15

15

P

F

VL

t

Where:

NGC8200

F1

F2

F3

G1

G2

RM-1

RM-2

RM-3

ANALYZER

10 cc/min.

RM-4

RM-5

By-Pass

Flow

800 cm/min

Typical

HV-1

HV-2

HV-3

HV-4

HV-5

HV-6

HV-7

HV-8

F4

F5

LD1

LD2

STANDARD

LIQUID DRAIN

STREAM 1

STREAM 2

BYPASS

LIQUID DRAIN

115 VAC

60 HZ

HEATER

125 WATT

HEATED CABINET